Introduction

Embroidery pricing often presents a complex array of variables, influenced by factors such as design complexity, thread count, and garment type. Understanding this landscape is crucial for anyone aiming to optimise their embroidery projects and manage costs effectively. With numerous elements at play, how can one ensure they are making cost-effective choices while still achieving high-quality results? This article explores the key factors that shape embroidery prices and provides practical strategies to help reduce expenses without compromising quality.

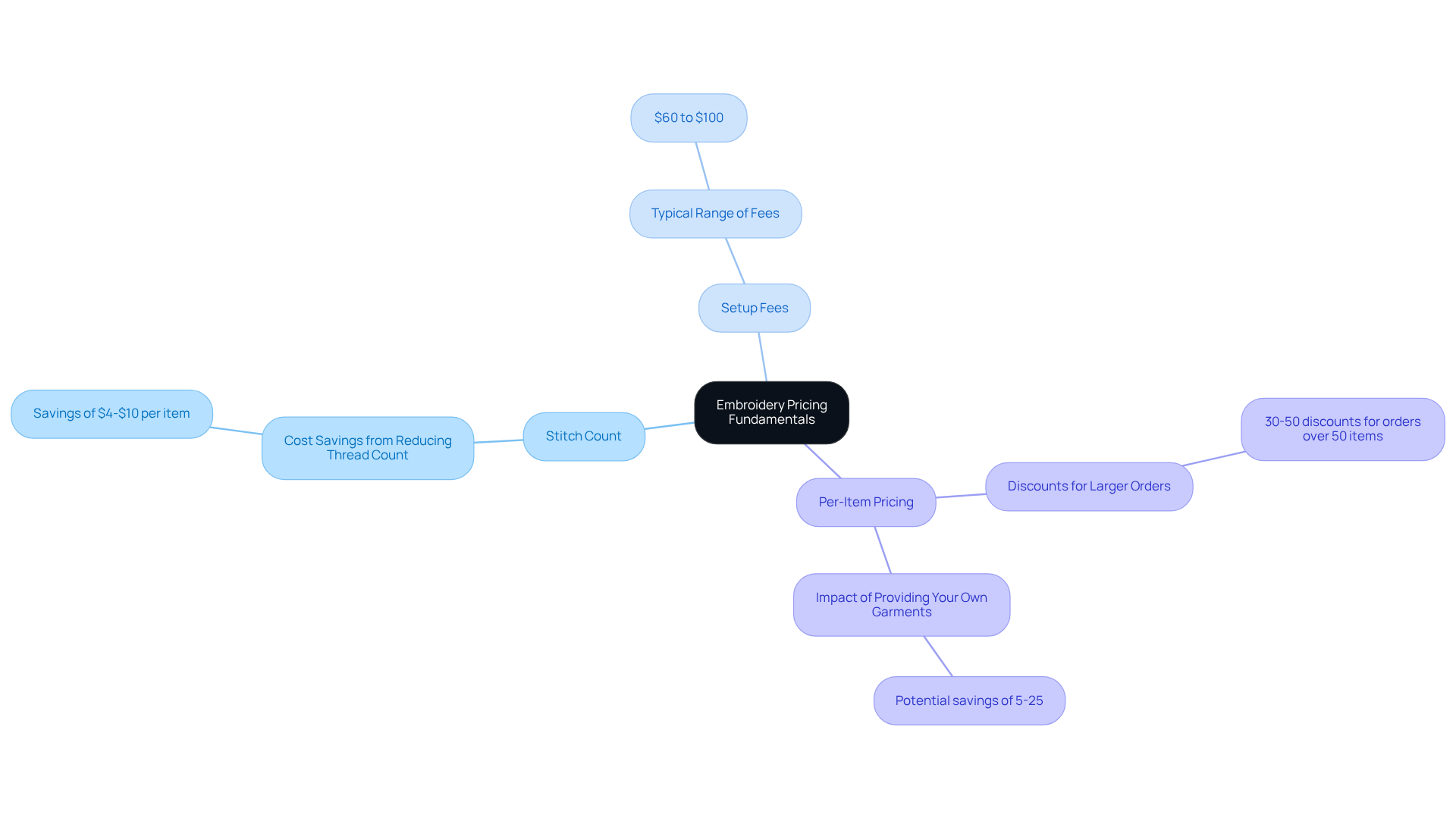

Explore the Fundamentals of Embroidery Pricing

Embroidery prices can be intricate, shaped by factors such as pattern complexity, thread count, and garment type. Understanding these fundamentals is essential for making informed decisions. Key terms include:

- Stitch Count: This indicates the total number of stitches in a design, which directly affects the cost. For instance, reducing a pattern from 12,000 threads to 8,000 can save between $4 and $10 per item.

- Setup Fees: These are one-time charges for preparing artwork for embroidery, typically ranging from $60 to $100, depending on the complexity and stitch count of the logo.

- Per-Item Pricing: This cost pertains to each individual item being embroidered and can vary based on quantity and design complexity. For larger orders, exceeding 50 items, discounts of 30-50% can be applied, significantly lowering the per-item price.

Grasping these terms enables better navigation of the embroidery prices landscape, allowing for strategic decisions that can optimise costs and enhance the overall value of embroidery projects. For example, opting for simpler patterns with fewer thread colours can lead to substantial savings, as most services include up to six colours in their base price, with additional colours increasing costs by $2 to $5 per item. Furthermore, customers can save 5-25% by providing their own garments for embroidery, as long as they meet the shop's fabric type and quality standards. By familiarising yourself with these elements, you can effectively manage your embroidery budget and achieve high-quality results.

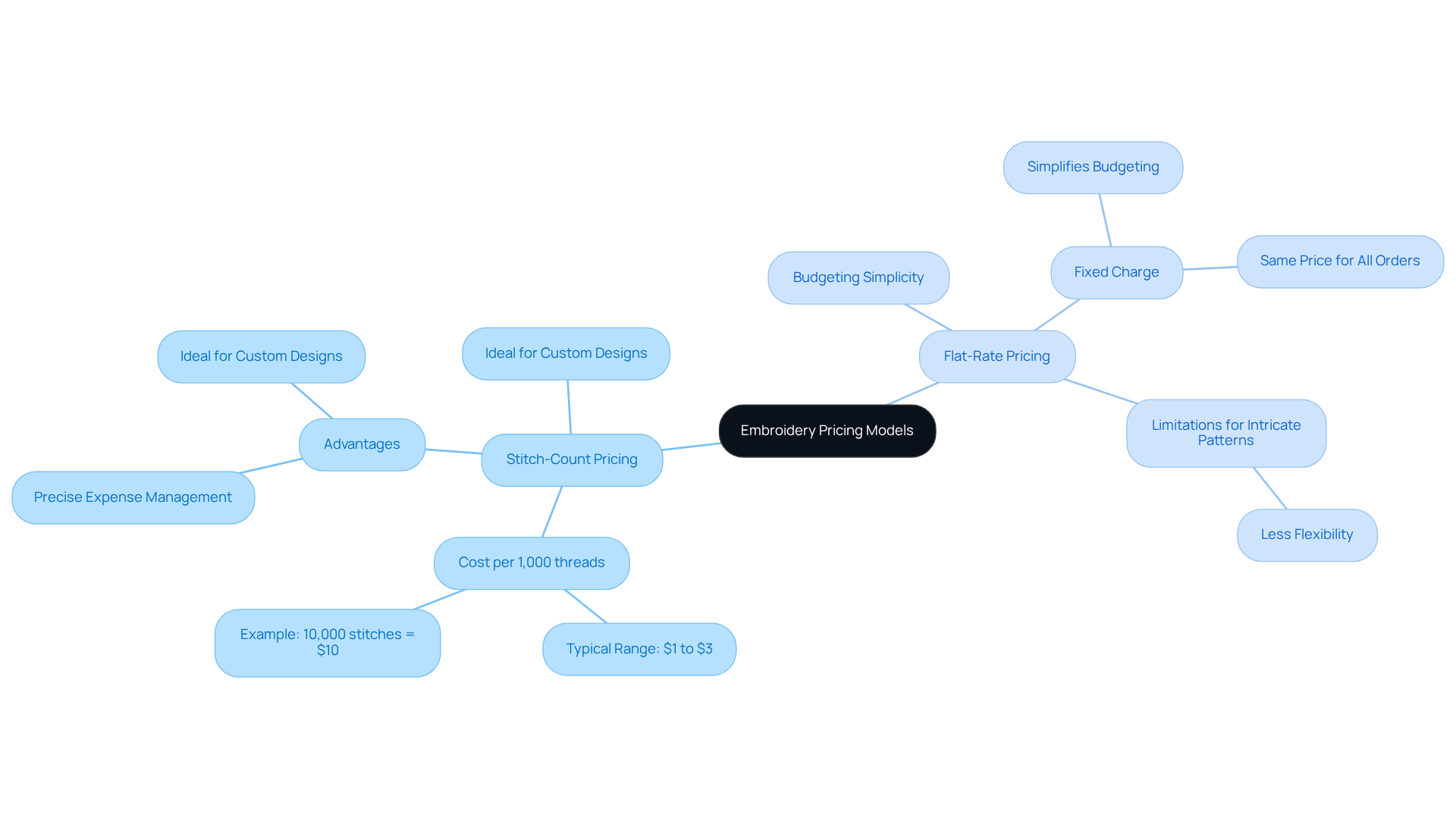

Analyze Core Pricing Models: Stitch-Count vs. Flat-Rate Systems

Embroidery pricing is primarily governed by two models:

-

Stitch-Count Pricing: This model charges based on the quantity of threads in a pattern, typically ranging from $1 to $3 per 1,000 threads. It is particularly advantageous for personalised creations, where thread counts can vary significantly, allowing for precise expense management. For instance, a logo with 10,000 threads would cost approximately $10 to embroider, making it an ideal choice for those who frequently request custom designs.

-

Flat-Rate Pricing: This method imposes a fixed charge per item, irrespective of the thread count. It simplifies budgeting, especially for large orders, as clients can avoid the complexities of seam calculations. However, it may lack the flexibility required for intricate patterns that necessitate a higher thread count.

Choosing the right pricing model for your project depends on your specific needs, including embroidery prices. If your organisation often requests custom creations, stitch-count pricing may provide greater clarity and control over your embroidery expenses, ensuring efficient planning while accommodating various creative complexities.

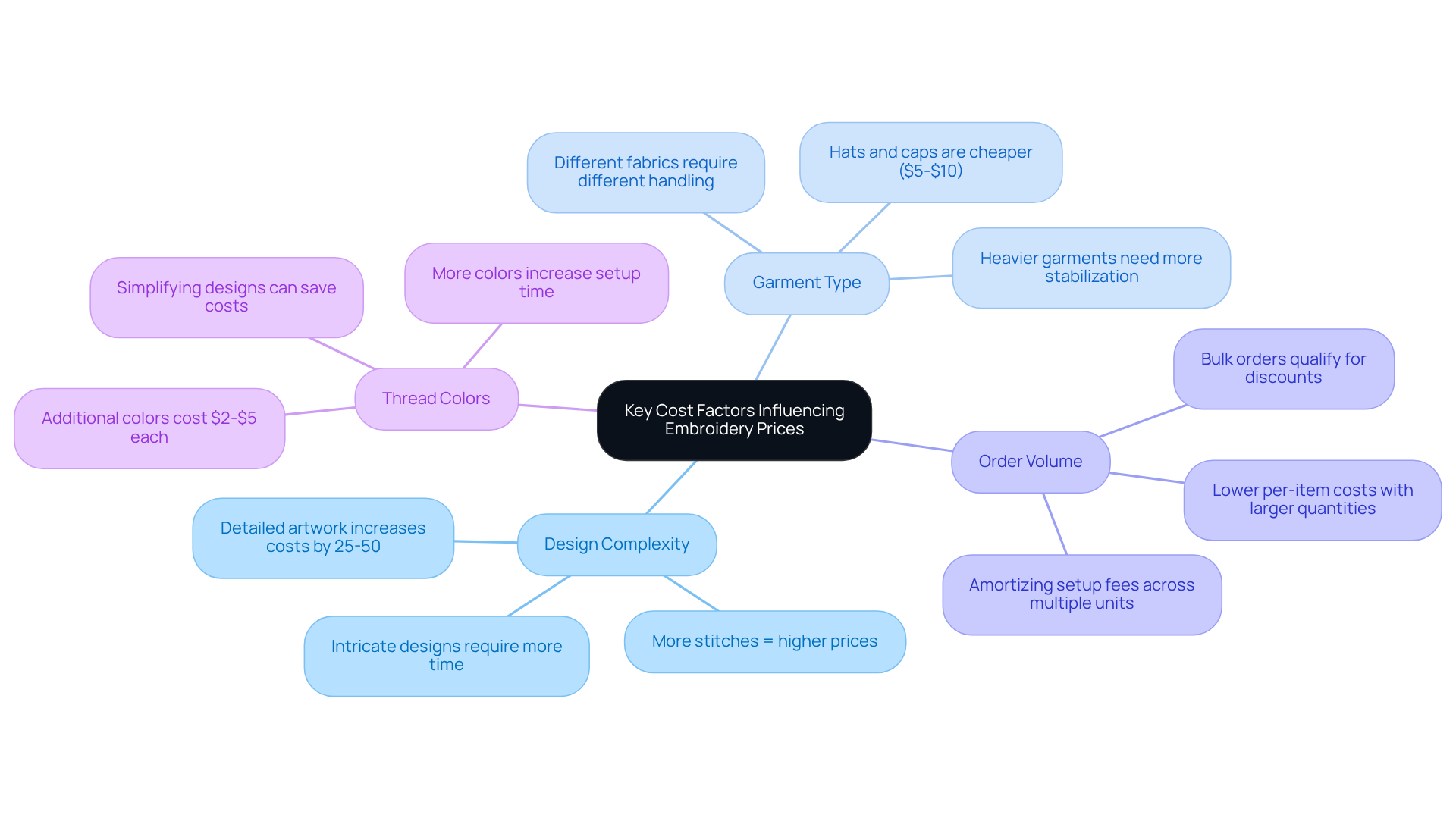

Identify Key Cost Factors Influencing Embroidery Prices

Several key factors influence embroidery prices:

-

Design complexity is a primary consideration. More intricate designs necessitate additional stitches and time, resulting in higher embroidery prices.

-

The type of garment also has a significant impact on embroidery prices. Different fabrics and styles can impact embroidery prices due to varying handling and stitching requirements.

-

Another critical factor is the order volume, which can impact embroidery prices. Larger orders often qualify for bulk discounts, which can lower the embroidery prices for each item.

-

Lastly, the number of thread colours used can affect embroidery prices. Utilising various thread colours may extend setup time and costs; therefore, streamlining designs can lead to savings.

By understanding these factors, you can strategize effectively, ensuring that your embroidery projects remain within budget.

Implement Cost-Reduction Strategies for Your Embroidery Projects

To effectively reduce embroidery costs, consider these key strategies:

-

Order in Bulk: Purchasing larger quantities can significantly lower per-item costs due to economies of scale. For example, ordering 100 items at once is often cheaper than placing two separate orders of 50. This approach is supported by Golders Toowoomba & Roma, which highlights the cost benefits of bulk ordering.

-

Simplify Designs: Streamlining your designs by reducing stitch counts and limiting the number of thread colours can lead to substantial savings. This not only cuts costs but also enhances the durability of the embroidery, making it a practical choice for long-term projects.

-

Negotiate Setup Fees: When making substantial purchases, engage with your supplier to discuss the possibility of waiving or reducing setup fees. Once a logo has been digitised and approved, it remains on record for future requests without incurring extra setup charges, which can further reduce your overall expenses.

-

Plan Ahead: Timing your orders strategically to avoid rush fees is crucial. By planning ahead, you can control expenses more effectively and ensure timely delivery without incurring additional costs.

Implementing these strategies can enhance the cost-effectiveness of your projects while keeping embroidery prices low and maintaining high-quality results. With projected average monthly running costs for the embroidery service in 2026 at $17,815, these strategies are essential for managing expenses.

Conclusion

Understanding the complexities of embroidery pricing is essential for making informed decisions regarding projects. Factors such as stitch count, setup fees, and garment type significantly influence overall costs. By grasping these elements, individuals can navigate the pricing landscape effectively, maximising value while minimising expenses.

Key insights emphasise the importance of selecting the appropriate pricing model - whether stitch-count or flat-rate - based on specific project needs. Additionally, recognising how design complexity, garment type, order volume, and thread colours impact pricing can lead to more strategic decisions. Implementing cost-reduction strategies, such as bulk ordering and simplifying designs, empowers individuals to manage their budgets while maintaining quality.

Ultimately, being equipped with knowledge about current embroidery pricing trends and cost-saving strategies is crucial for anyone involved in embroidery projects. By applying these insights, individuals can achieve high-quality results while ensuring their projects remain financially viable. Embracing these principles fosters smarter spending and enhances the success of embroidery endeavours.

Frequently Asked Questions

What factors influence embroidery pricing?

Embroidery pricing is influenced by factors such as pattern complexity, thread count, and garment type.

What is stitch count and how does it affect cost?

Stitch count indicates the total number of stitches in a design, and it directly affects the cost. For example, reducing a pattern from 12,000 stitches to 8,000 can save between $4 and $10 per item.

What are setup fees in embroidery pricing?

Setup fees are one-time charges for preparing artwork for embroidery, typically ranging from $60 to $100, depending on the complexity and stitch count of the logo.

How does per-item pricing work in embroidery?

Per-item pricing refers to the cost for each individual item being embroidered, which can vary based on the quantity and design complexity. Discounts of 30-50% may apply for larger orders exceeding 50 items.

How can I save on embroidery costs?

You can save on embroidery costs by opting for simpler patterns with fewer thread colours, as most services include up to six colours in their base price, with additional colours costing $2 to $5 each. Additionally, providing your own garments that meet the shop's fabric type and quality standards can lead to savings of 5-25%.

Why is it important to understand embroidery pricing fundamentals?

Understanding embroidery pricing fundamentals enables better navigation of costs, allowing for strategic decisions that can optimise expenses and enhance the overall value of embroidery projects.