Introduction

Choosing the right clothing for mechanics is not just about looks; it plays a vital role in workplace safety and efficiency. Quality mechanic apparel enhances comfort and durability while showcasing a commitment to professionalism and ethical practises.

With numerous options available, how can businesses ensure they make the best choices for their teams? This article explores key considerations for selecting quality mechanic clothing, examining:

- Materials

- Fit

- Safety features

- Sustainable sourcing

These insights will help organisations make informed decisions that benefit both their employees and the environment.

Identify Key Materials for Durability and Comfort

When selecting mechanic clothing, it is crucial to prioritise materials that offer both durability and comfort. Fabrics like cotton-polyester blends, ripstop, and canvas emerge as top choices. Cotton is well-known for its breathability and comfort, while polyester enhances durability and moisture-wicking capabilities. For instance, mechanic clothing made from a blend of 65% polyester and 35% cotton strikes an ideal balance, making it suitable for the demanding tasks technicians encounter daily.

Moreover, mechanic clothing made from fabrics treated for oil and stain resistance is vital in a technician's work environment. Certifications that indicate a fabric's performance under various conditions are essential to ensure compliance with safety and comfort standards. Investing in high-quality materials not only enhances the wearer's experience but also bolsters a professional image, signalling competence and attention to detail.

Ensure Proper Fit and Functional Design

To ensure that mechanic clothing fits properly and meets the demands of the job, it is crucial to consider the specific tasks that mechanics perform. Look for attire equipped with adjustable features such as:

- Elastic waistbands

- Reinforced seams

- Multiple pockets for tools

A well-fitted outfit should allow for a full range of motion without being overly loose, as this can create safety hazards; loose or poorly fitting attire can lead to accidents, such as getting caught in machinery or causing trips. For instance, overalls with adjustable straps can accommodate various body types while enhancing comfort. Additionally, designs that incorporate stretch panels or gussets significantly improve mobility, enabling mechanics to navigate their work environment with ease.

Employees in suitably tailored attire can move freely, enhancing productivity and focus. Conducting fittings for each team member is essential to ensure that attire meets individual needs, ultimately fostering a safer and more productive workplace.

At Jon Monsir Uniforms, we assure workwear garment quality through rigorous quality assurance practices, including controlled specifications and in-line checks. Our dedication to personalization enables tailored solutions that address the distinct needs of different sectors, ensuring that the appropriate mechanic clothing not only fosters a professional look but also serves a vital function in workplace security and efficiency.

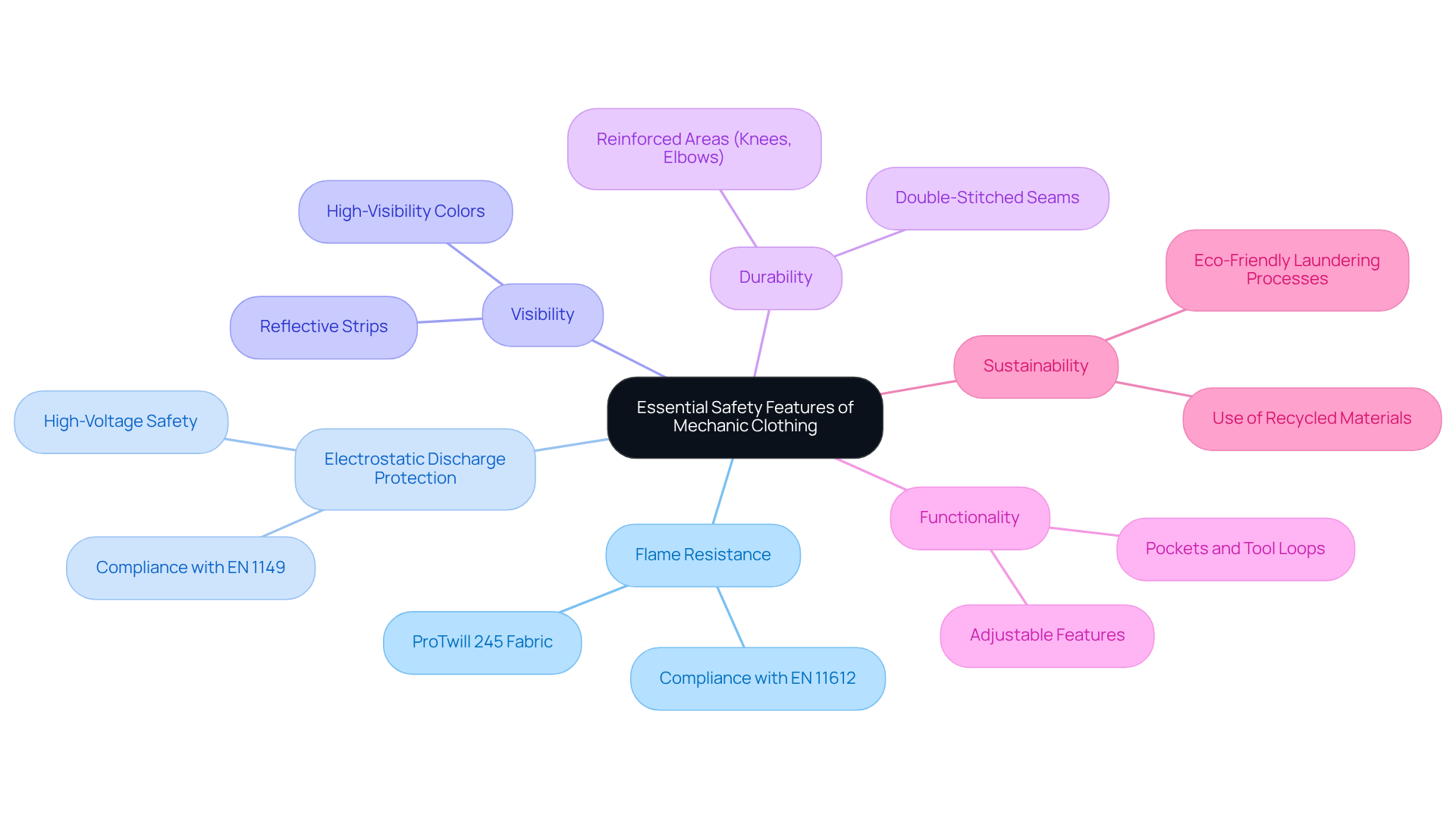

Incorporate Essential Safety Features

Mechanic clothing must prioritize essential protective features to shield workers from various hazards. Mechanic clothing made from flame-resistant fabrics is crucial, particularly for those working near engines or in environments where sparks are a risk. Mechanic clothing made from fabrics like ProTwill 245 combines durability with safety, ensuring mechanics are protected from potential fire hazards.

Compliance with EN 1149 for electrostatic discharge protection is vital, especially in high-voltage settings. High-visibility colours and reflective strips enhance visibility in low-light conditions, significantly reducing accident risks. Additionally, reinforced areas, such as knees and elbows, are essential for durability, as these parts of the uniform often endure considerable wear and tear.

Uniforms featuring double-stitched seams and added padding can greatly improve both protection and longevity. Practical elements like pockets and loops for tools enhance functionality, enabling mechanics to work efficiently. It is imperative that all mechanic clothing adheres to relevant safety standards, such as AS/NZS 4602 for high-visibility clothing, to ensure a safe working environment.

Moreover, incorporating sustainable materials in clothing production contributes to reducing carbon emissions, aligning with contemporary environmental standards.

Prioritize Sustainable and Ethical Sourcing

When selecting mechanic clothing, it is crucial to prioritise suppliers that are committed to sustainable and ethical sourcing practises. Jon Monsir Apparel exemplifies this commitment by offering tailored attire made from high-quality materials, such as organic cotton and recycled polyester, which significantly reduce environmental impact. Their design and manufacturing process ensures that each garment meets the specific needs of the wearer, enhancing both comfort and durability.

For instance, sustainable uniforms from Jon Monsir are designed to last twice as long as conventional options, resulting in fewer replacements and less waste. Collaborating with suppliers like Jon Monsir, who emphasise sustainability and ethical practises, can enhance your brand's reputation and attract environmentally conscious consumers, especially those interested in mechanic clothing, aligning your business with the growing trend toward responsible procurement.

Moreover, Jon Monsir's partnerships with ethical manufacturers guarantee fair labour practises and transparency throughout their supply chains. This approach showcases how responsible sourcing can positively impact both the environment and society.

Conclusion

In conclusion, selecting the right mechanic clothing is crucial for ensuring both comfort and safety in the workplace. By prioritising high-quality materials, proper fit, functional design, essential safety features, and sustainable sourcing, businesses can enhance their team's performance while projecting a professional image. These factors not only contribute to the well-being of mechanics but also reflect a commitment to quality and responsibility.

The importance of durable fabrics, such as cotton-polyester blends, cannot be overstated. Features like adjustable waistbands and reinforced seams are necessary for optimal functionality. Safety considerations, including flame-resistant materials and adherence to relevant standards, are vital for protecting workers in potentially hazardous environments. Furthermore, prioritising sustainable and ethical sourcing practises can significantly benefit both the environment and a company's reputation.

Ultimately, investing in quality mechanic clothing transcends aesthetics; it plays a pivotal role in promoting safety, efficiency, and sustainability in the workplace. By choosing uniforms that align with these best practises, businesses can ensure their mechanics are well-equipped to handle demanding tasks while fostering a culture of care and responsibility within their teams.

Frequently Asked Questions

What materials should be prioritised when selecting mechanic clothing?

When selecting mechanic clothing, it is crucial to prioritise materials that offer both durability and comfort, such as cotton-polyester blends, ripstop, and canvas.

What are the benefits of using cotton in mechanic clothing?

Cotton is well-known for its breathability and comfort, making it a favourable choice for mechanic clothing.

How does polyester enhance mechanic clothing?

Polyester enhances durability and moisture-wicking capabilities, which are beneficial for the demanding tasks technicians encounter daily.

What is an ideal fabric blend for mechanic clothing?

A blend of 65% polyester and 35% cotton strikes an ideal balance of durability and comfort for mechanic clothing.

Why is oil and stain resistance important in mechanic clothing?

Fabrics treated for oil and stain resistance are vital in a technician's work environment to maintain cleanliness and functionality.

What should be considered regarding fabric certifications?

Certifications indicating a fabric's performance under various conditions are essential to ensure compliance with safety and comfort standards.

How does investing in high-quality materials affect a technician's image?

Investing in high-quality materials enhances the wearer's experience and bolsters a professional image, signalling competence and attention to detail.