Introduction

Choosing the right mechanic jumpsuits for a team is not merely a stylistic choice; it’s a crucial decision that significantly affects safety, comfort, and productivity in the workplace. As the demand for durable and functional workwear continues to rise, organisations encounter the challenge of sifting through a vast array of options and specifications.

What key factors should be considered when selecting these essential uniforms?

How can teams ensure they are making informed choices tailored to their specific needs?

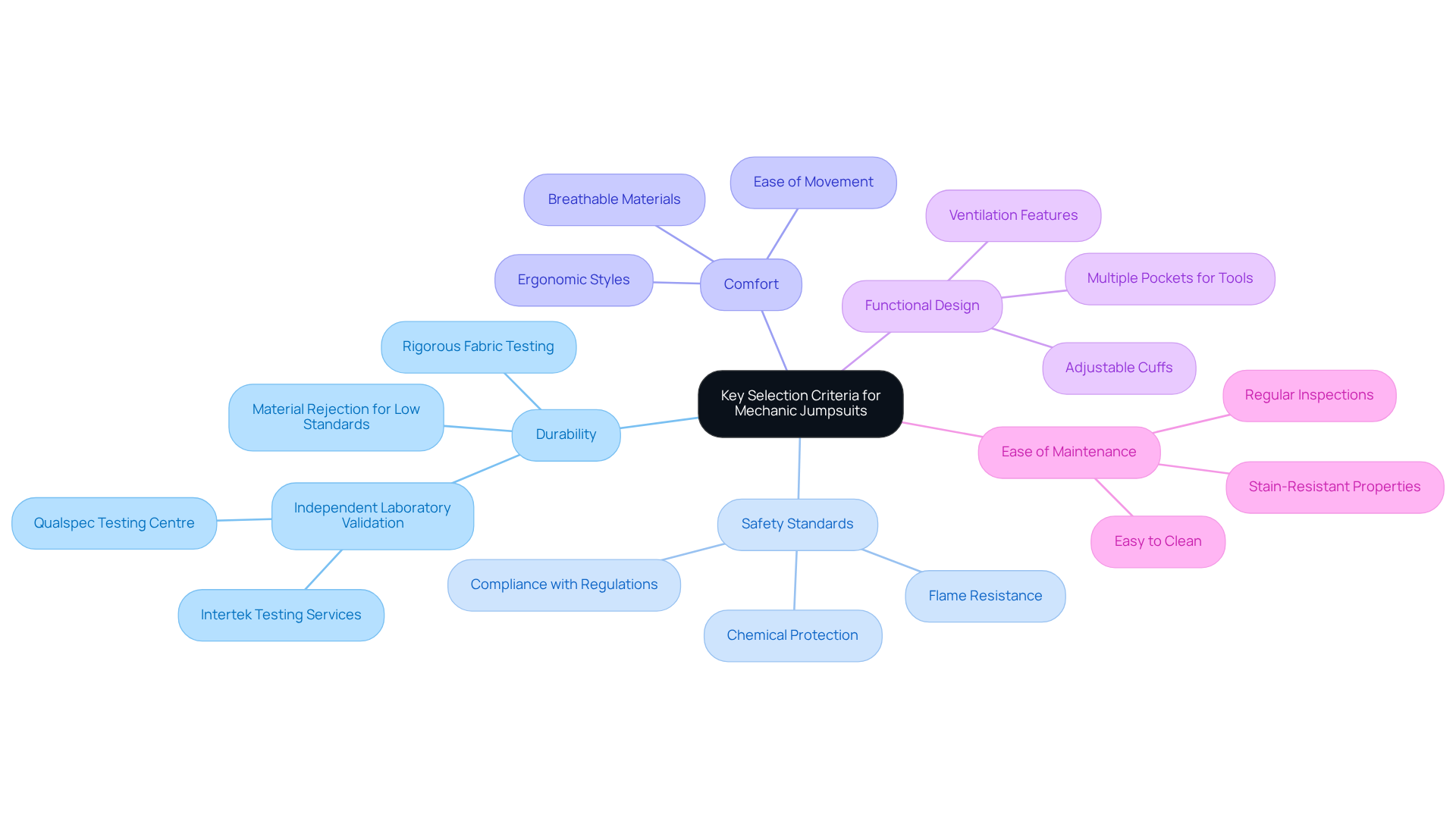

Identify Key Selection Criteria for Mechanic Jumpsuits

When selecting mechanic jumpsuits, several key criteria must be considered:

-

Durability: Mechanic coveralls need to withstand the rigours of daily wear and tear. At Jon Monsir Uniforms, we ensure durability through rigorous fabric testing, validated by independent laboratories such as Intertek Testing Services and Qualspec Testing Centre. Our testing includes assessments for colour fastness, crocking, dry-cleaning solvents, light exposure, water resistance, and aging. Materials that do not meet our high standards are rejected and rectified before production proceeds.

-

Safety Standards: It is crucial to ensure that the protective suits comply with relevant safety regulations, including flame resistance and chemical protection, tailored to the specific work environment.

-

Comfort: Comfort is paramount, as mechanics often work long hours. It is advisable to select outfits made from breathable materials and ergonomic styles that allow for ease of movement.

-

Functional Design: Features such as multiple pockets for tools, adjustable cuffs, and ventilation can significantly enhance functionality and convenience.

-

Ease of Maintenance: Given the nature of the work, coveralls should be easy to clean and maintain, ideally possessing stain-resistant properties.

By concentrating on these criteria, organisations can select mechanic jumpsuits that not only protect their employees but also enhance their overall work experience.

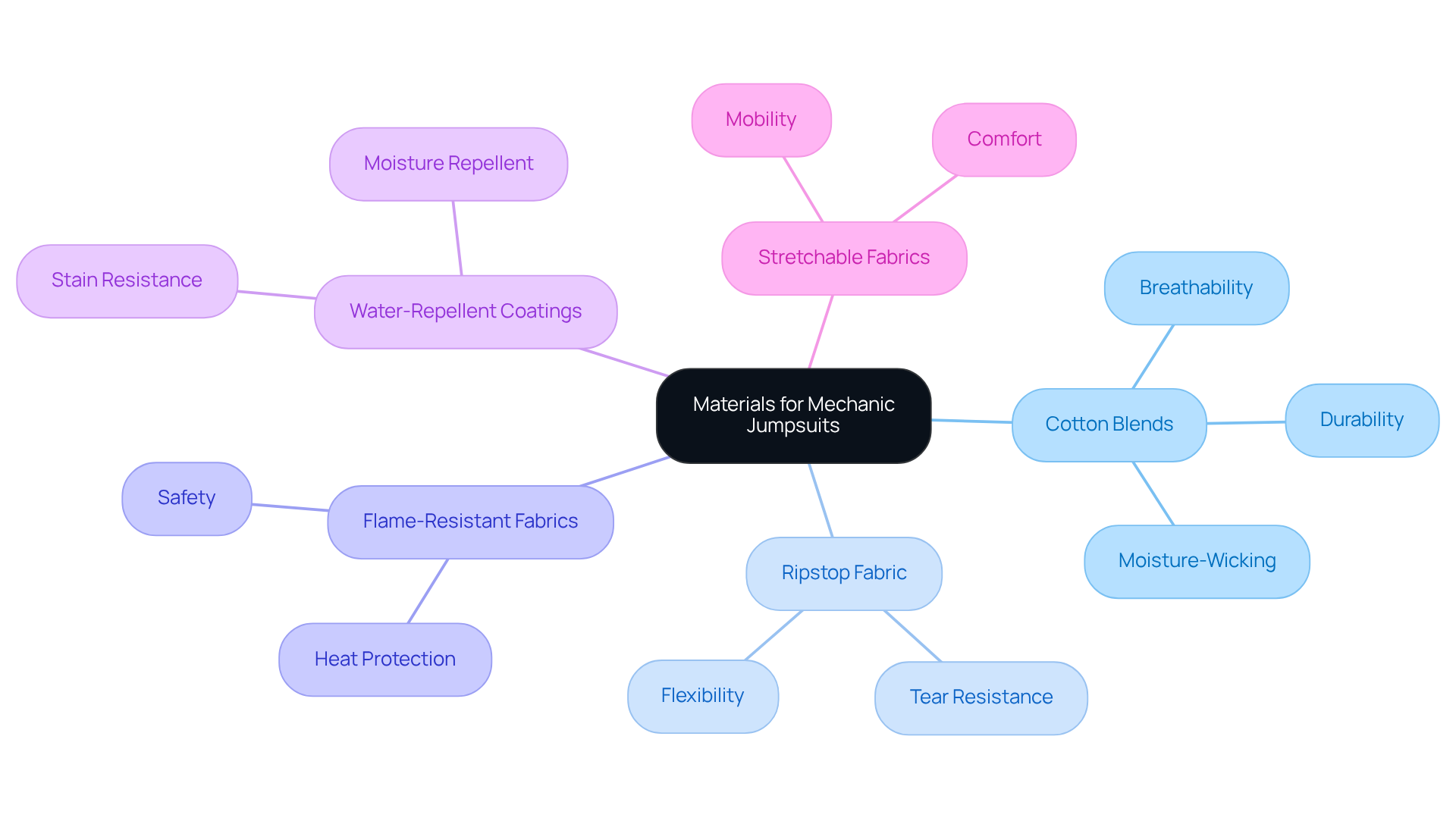

Choose Appropriate Materials for Enhanced Comfort and Durability

Selecting the right materials for mechanic jumpsuits is crucial to ensure both comfort and durability. Here are some recommended options:

-

Cotton Blends: A combination of cotton and polyester provides breathability and comfort while enhancing durability. This blend aids in moisture-wicking, keeping the wearer dry. According to Technavio, the coverall market is projected to grow by $2.31 billion at a CAGR of 8.09% from 2023 to 2028, highlighting the rising demand for high-quality workwear fabrics.

-

Ripstop Fabric: Designed to resist tearing and ripping, ripstop fabric is ideal for high-stress environments. The Blaklader 6166 Industry Overall Stretch, made from 98% cotton and 2% elastolefin, exemplifies this durability while offering comfort and flexibility.

-

Flame-Resistant Fabrics: For mechanics working near heat sources, flame-resistant fabrics provide a critical layer of safety, protecting against potential workplace hazards.

-

Water-Repellent Coatings: Garments with water-repellent finishes are advisable to guard against spills and stains, ensuring longevity. The Portwest C802 Standard Coveralls, priced at $36.99, feature a water-resistant coating that repels moisture, enhancing their durability.

-

Stretchable Fabrics: Incorporating materials like elastane can improve mobility, allowing for a greater range of motion during repairs. This flexibility is crucial for effective performance in various mechanical tasks.

By prioritising these materials, organisations can ensure that their mechanic jumpsuits are not only comfortable but also capable of withstanding the demands of the job. It is also important to avoid common pitfalls, such as selecting fabrics that lack breathability or durability, which can lead to discomfort and reduced safety for the wearer. Integrating professional insights and case studies, such as the effectiveness of heavy-duty cotton drill overalls, can further aid in selecting the best materials for workwear.

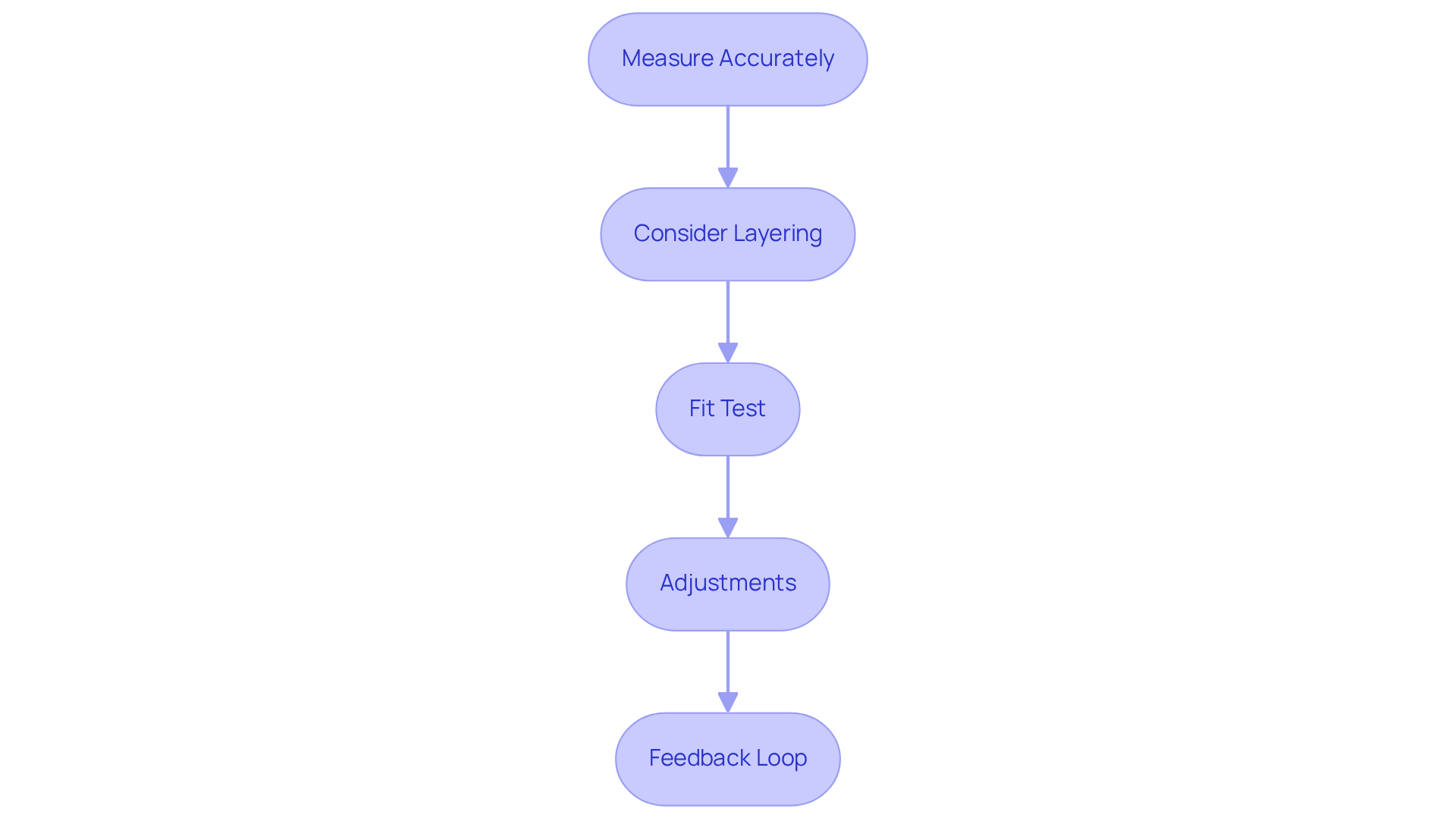

Ensure Proper Sizing and Fit for Optimal Performance

Obtaining the right fit for mechanic jumpsuits is crucial for ensuring comfort and safety in the workplace. Here are essential steps to ensure proper sizing:

- Measure Accurately: Use a measuring tape to take precise measurements of the chest, waist, and inseam. Accurate measurements are essential for selecting the correct size.

- Consider Layering: Mechanics often wear additional layers beneath their work attire. Choose a size that accommodates this layering without sacrificing fit.

- Fit Test: Whenever possible, have team members try on different sizes and styles to find the best fit. Focus on ease of movement and comfort in various positions, as these factors are vital for effective performance.

- Adjustments: Be ready to make necessary adjustments. If an outfit is slightly oversized, altering it in key areas such as the waist and sleeves can enhance fit and functionality.

- Feedback Loop: Foster an environment where team members can provide feedback on fit and comfort. This input is invaluable for refining future orders and ensuring optimal performance.

By implementing these steps, organisations can significantly enhance the fit of their mechanic jumpsuits, which leads to improved safety and comfort for their teams.

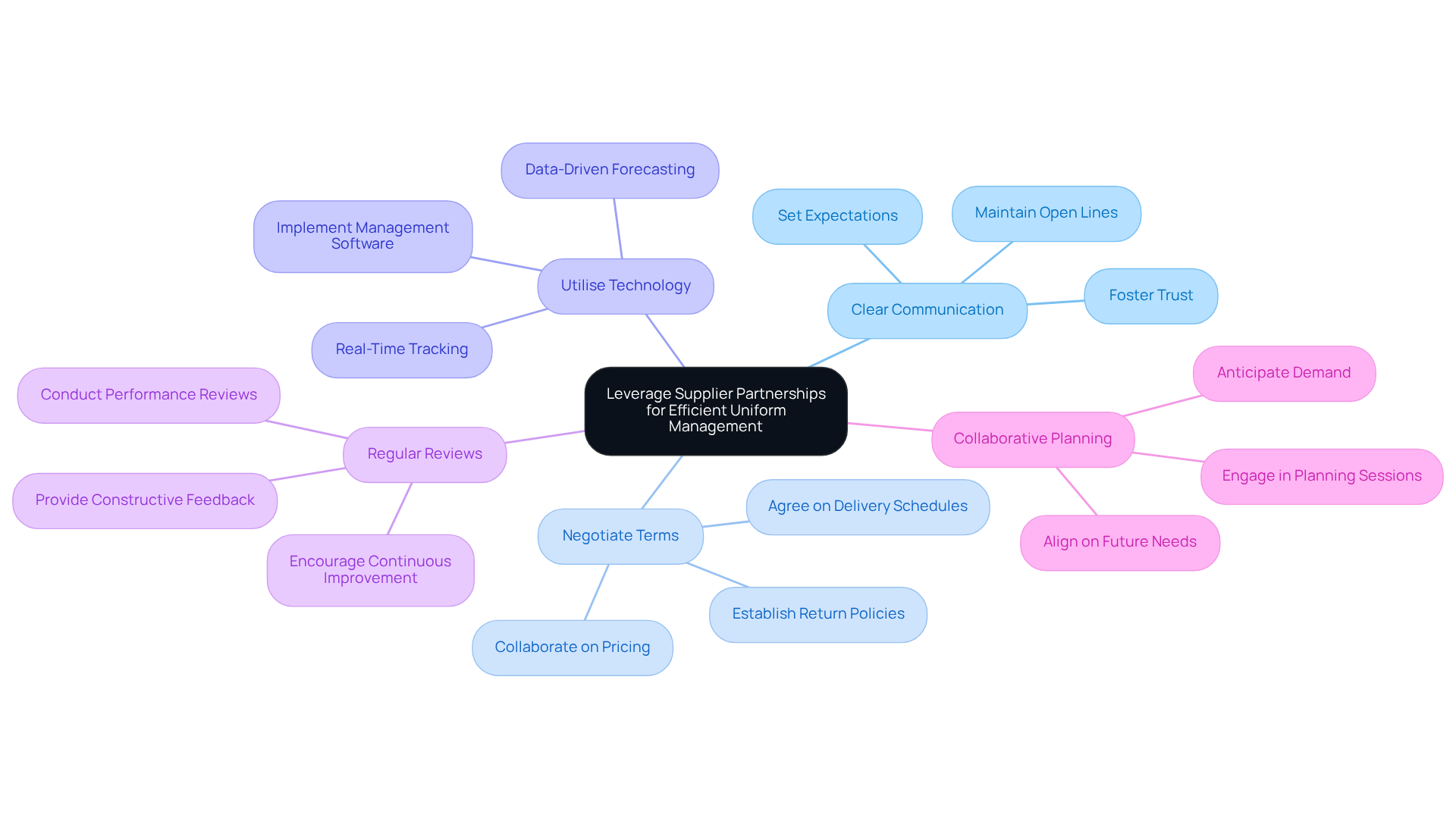

Leverage Supplier Partnerships for Efficient Uniform Management

Building strong partnerships with uniform suppliers, such as Jon Monsir Uniforms, is essential for enhancing the efficiency of uniform management. To leverage these relationships effectively, consider the following key strategies:

-

Establish Clear Communication: Maintaining open lines of communication with suppliers is crucial. This ensures that expectations regarding timelines, pricing, and quality are clearly understood and met. Transparent communication fosters trust and minimises misunderstandings.

-

Negotiate Terms: Collaborate with suppliers to negotiate favourable terms, including pricing, delivery schedules, and return policies. This proactive approach can lead to improved service and cost savings.

-

Utilise Technology: Implement uniform management software that integrates seamlessly with supplier systems. Such technology enables real-time tracking of orders and inventory management, significantly reducing stock-outs and enhancing operational efficiency. Data-driven forecasting can reduce stock-outs by up to 30%, underscoring the value of these systems.

-

Regular Reviews: Conduct regular performance reviews of suppliers to ensure they consistently meet quality and service standards. Providing constructive feedback encourages continuous improvement and strengthens the partnership.

-

Collaborative Planning: Engage suppliers in planning sessions to align on future needs. This collaboration ensures that suppliers can anticipate demand and respond promptly, preventing delays in uniform delivery.

By implementing these strategies and partnering with Jon Monsir Uniforms, organisations can optimise their uniform procurement processes. This ensures that teams are always well-equipped and professionally presented, with access to fast local supply, inclusive sizing, and durable, comfortable fabrics that withstand repeated wear and wash cycles.

Conclusion

Selecting the right mechanic jumpsuits for a team is a complex process that requires careful consideration of several factors. Prioritising durability, safety standards, comfort, functional design, and ease of maintenance ensures that the chosen coveralls not only protect employees but also enhance their work experience. By following these principles, organisations can foster a safer and more efficient work environment.

Key insights highlight the significance of choosing appropriate materials, such as cotton blends and flame-resistant fabrics, which contribute to both comfort and durability. Furthermore, ensuring the proper sizing and fit is essential for optimal performance, as it directly impacts the comfort and safety of the mechanics. Building strong partnerships with uniform suppliers also streamlines uniform management, facilitating better communication, negotiation, and technology integration.

Ultimately, investing time and resources in selecting the best mechanic jumpsuits is crucial for cultivating a productive and safe workplace. As the demand for high-quality workwear continues to grow, organisations should prioritise these best practises to effectively equip their teams. By doing so, they not only enhance employee satisfaction but also improve overall operational efficiency.

Frequently Asked Questions

What are the key criteria to consider when selecting mechanic jumpsuits?

The key criteria include durability, safety standards, comfort, functional design, and ease of maintenance.

Why is durability important for mechanic jumpsuits?

Durability is important because mechanic coveralls need to withstand the rigours of daily wear and tear. At Jon Monsir Uniforms, durability is ensured through rigorous fabric testing for various factors such as colour fastness and water resistance.

What safety standards should mechanic jumpsuits comply with?

Mechanic jumpsuits should comply with relevant safety regulations, including flame resistance and chemical protection, tailored to the specific work environment.

How does comfort play a role in selecting mechanic jumpsuits?

Comfort is crucial as mechanics often work long hours. It is advisable to select outfits made from breathable materials and ergonomic styles that allow for ease of movement.

What functional design features should be considered for mechanic jumpsuits?

Features such as multiple pockets for tools, adjustable cuffs, and ventilation can significantly enhance the functionality and convenience of mechanic jumpsuits.

Why is ease of maintenance important for mechanic jumpsuits?

Ease of maintenance is important because the nature of the work can lead to heavy soiling, so coveralls should be easy to clean and maintain, ideally possessing stain-resistant properties.