Introduction

Selecting the appropriate mechanic sweatshirt is crucial for enhancing a professional's comfort and efficiency on the job. Key features such as durability, moisture-wicking properties, and ethical production practises play a significant role in determining the quality of a garment. Given the multitude of options available, mechanics must consider how to choose sweatshirts that not only perform effectively but also reflect sustainable values. This article explores best practises for selecting mechanic sweatshirts, emphasising essential attributes that improve both functionality and environmental responsibility.

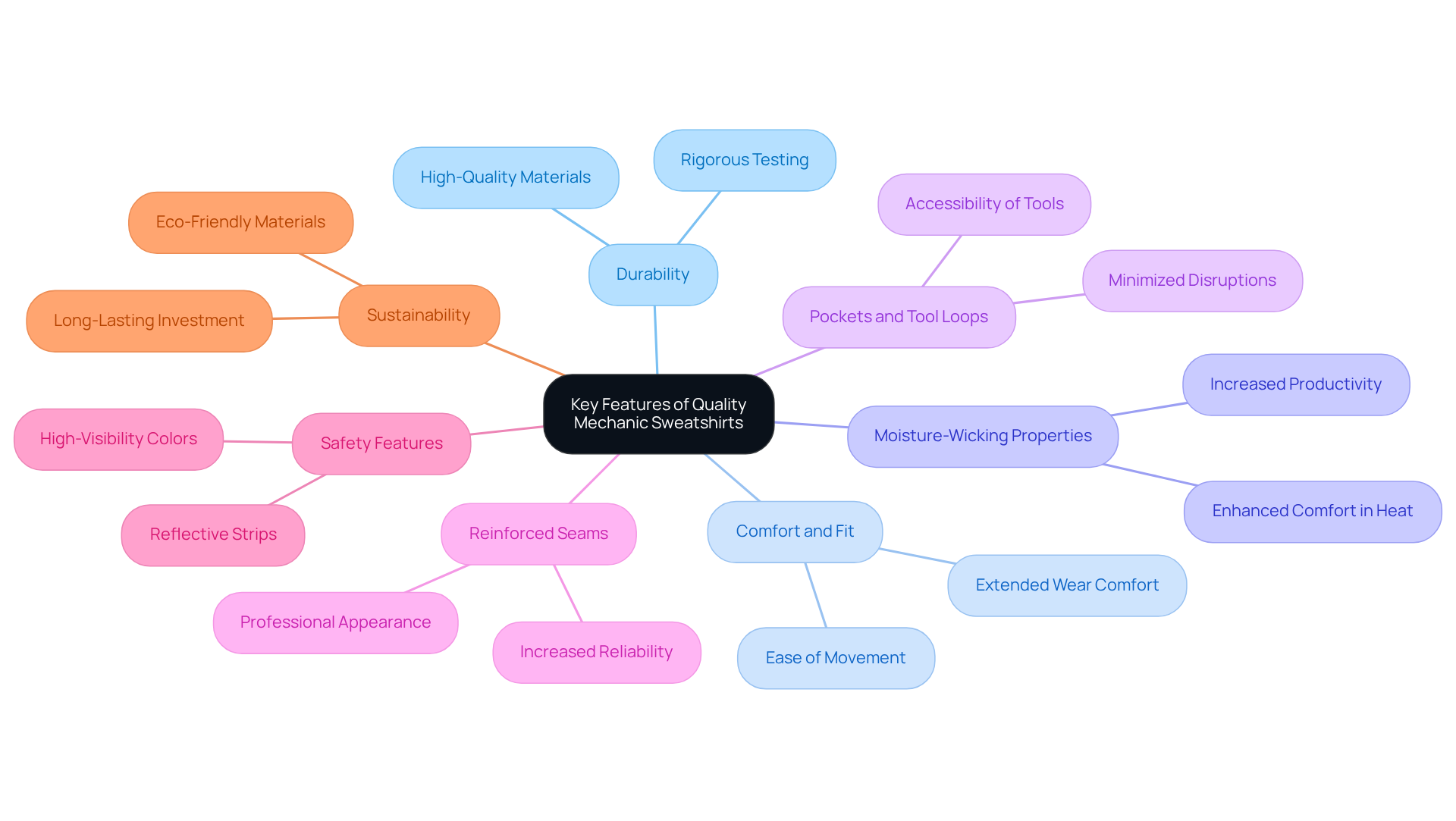

Identify Key Features of Quality Mechanic Sweatshirts

When selecting a mechanic sweatshirt, several key features are essential for enhancing functionality and comfort.

-

Durability is paramount. Opt for garments crafted from high-quality materials like cotton-polyester blends or ripstop fabrics, known for their ability to endure the rigours of mechanical work. At Jon Monsir Uniforms, our fabrics undergo stringent testing through independent laboratories such as Intertek Testing Services and Qualspec Testing Centre. This testing evaluates colour fastness, wear resistance, and water resistance, ensuring longevity and minimising the need for replacements. Materials that do not meet these standards are corrected by the mill and resubmitted for approval before production continues.

-

Comfort and Fit are also critical. A well-fitted garment should facilitate ease of movement without being too tight or loose. This balance is vital for comfort during extended work hours, allowing mechanics to perform tasks efficiently. As industry expert Sanowar Ali states, 'The suitable fabric of a mechanic sweatshirt ensures the uniform's longevity and provides comfort and protection throughout the workday.'

-

Moisture-Wicking Properties are another feature to consider. Garments that incorporate moisture-wicking technology are particularly advantageous in hot working conditions, helping to keep mechanics dry and comfortable, which in turn enhances overall productivity.

-

Pockets and Tool Loops significantly boost productivity. Functional designs that include pockets for tools and personal items ensure that essential items are always within reach, minimising disruptions during work.

-

Reinforced Seams contribute to durability. Sweatshirts with reinforced seams are less likely to tear, providing reliability in demanding environments. This durability is crucial for maintaining a professional appearance while ensuring the garment can withstand the challenges of the job.

-

Safety Features should not be overlooked. Garments equipped with reflective strips or high-visibility colours enhance visibility in low-light conditions, thereby reducing the risk of accidents in busy workshop environments.

-

Sustainability is increasingly important. With a growing focus on environmentally conscious practises, selecting garments made from sustainable materials can contribute to a greener future. As sustainability expert Leonie Biesen emphasises, "Investing in durable workwear is essential for businesses keen to provide their employees with comfortable, long-lasting uniforms."

By prioritising these features, mechanics can select mechanic sweatshirts that not only project a professional image but also provide exceptional performance under the demands of their work.

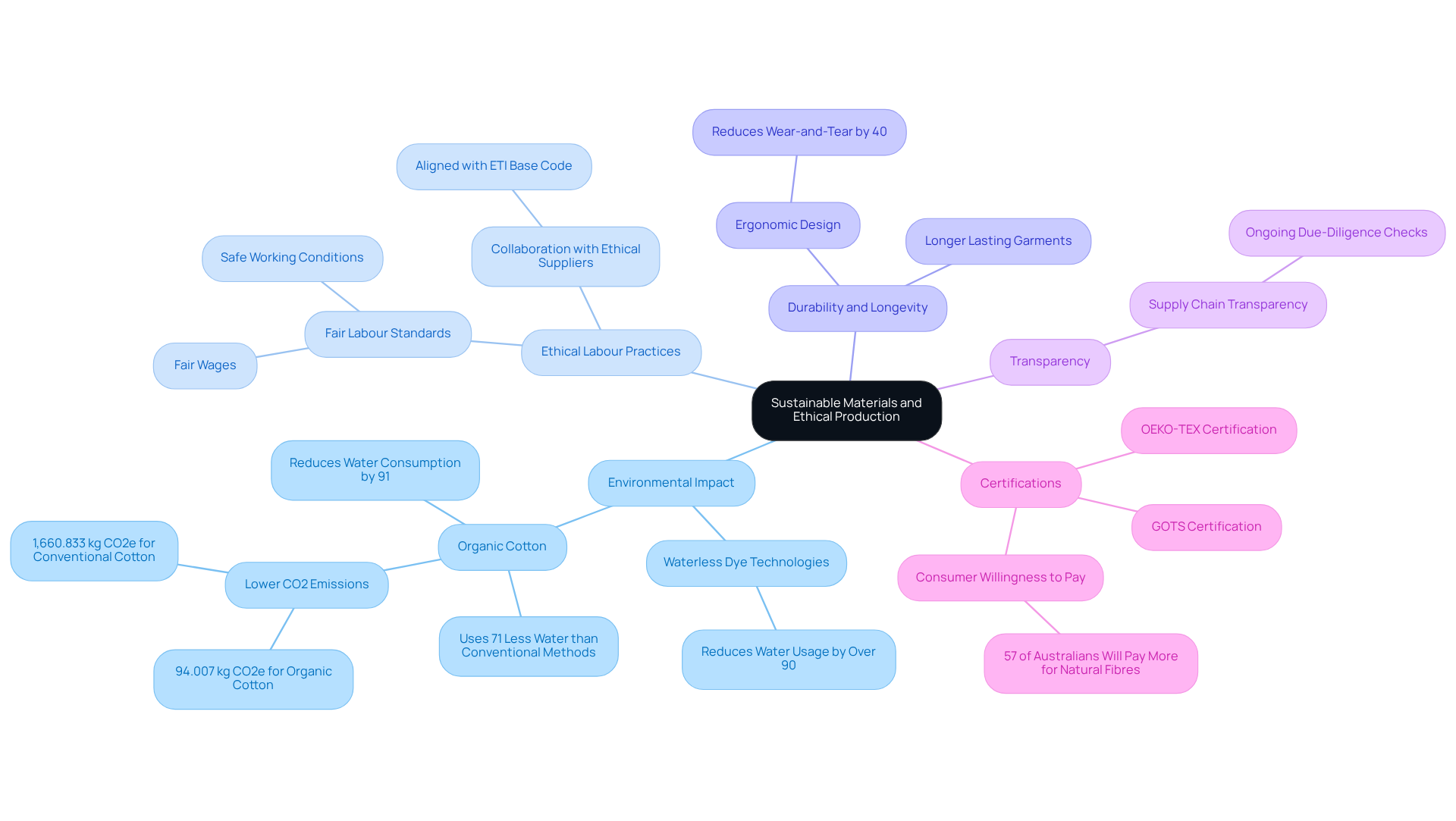

Prioritize Sustainable Materials and Ethical Production

Choosing mechanic sweatshirts made from sustainable materials and produced through ethical practises is essential for several compelling reasons.

-

Environmental Impact: Opting for sweatshirts made from organic cotton or recycled polyester significantly mitigates environmental harm. For example, organic cotton can reduce water consumption by up to 91% compared to conventional practises, making it a more sustainable choice.

-

Ethical Labour Practises: Ensuring that the production process adheres to fair labour practises is crucial. This includes providing safe working conditions and fair wages for workers. Jon Uniforms prioritises ethical sourcing by collaborating exclusively with suppliers who align with the Ethical Trading Initiative (ETI) Base Code. This commitment ensures safe working conditions, fair wages, and respect for workers' rights, contributing to a more equitable industry.

-

Durability and Longevity: Sustainable materials often demonstrate superior durability, resulting in longer-lasting garments that require less frequent replacement. Research indicates that garments produced through ergonomic design can reduce wear-and-tear by up to 40%, further minimising waste.

-

Transparency: Brands that maintain transparency in their supply chain empower consumers to understand the sourcing and production processes. Jon Uniforms conducts ongoing due-diligence checks with their suppliers, fostering trust and encouraging responsible purchasing decisions.

-

Certifications: It is advisable to look for garments with certifications such as GOTS (Global Organic Textile Standard) or OEKO-TEX, which signify adherence to rigorous environmental and social standards. Notably, 57% of Australians are willing to pay more for clothing made from natural fibres, underscoring the demand for certified sustainable products.

By prioritising these factors, organisations not only enhance their brand reputation but also contribute positively to environmental sustainability and social responsibility.

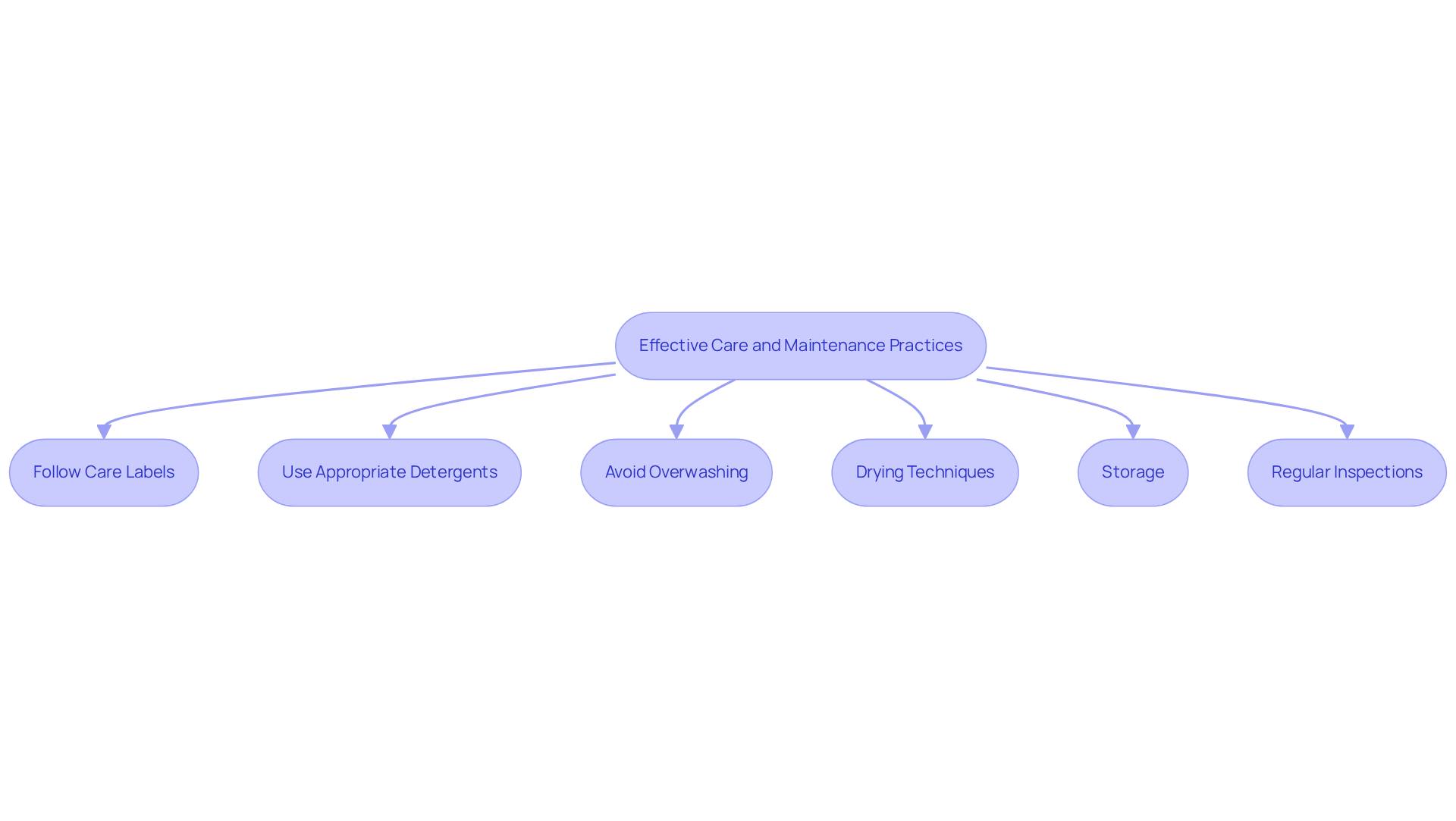

Implement Effective Care and Maintenance Practices

To ensure the longevity of the mechanic sweatshirt from Jon Monsir Uniforms, effective care and maintenance practices are essential.

-

Follow Care Labels: Adhering to the washing instructions on the care label is crucial to avoid damaging the fabric. Ignoring these guidelines can lead to issues such as shrinkage and fading, significantly reducing the lifespan of the garment. We provide role-specific care guides tailored to different industries, such as healthcare and hospitality, to help you maintain your uniforms effectively.

-

Use Appropriate Detergents: Select detergents that are compatible with the fabric type. Avoid harsh chemicals that can degrade the material, as many conventional detergents contain harmful substances that may affect both the garment and the environment. Dr. Kyle Grant, CEO of Oxwash, emphasises that "many laundry detergents contain chemicals, such as phosphates, surfactants, and optical brighteners, which can be harmful to aquatic life when they enter waterways through wastewater discharge."

-

Avoid Overwashing: Limit washing to occasions when the garment is visibly dirty. Spot cleaning is an effective method for addressing minor stains without subjecting the fabric to unnecessary wear. Over-washing can lead to quicker deterioration and increased landfill waste. In fact, statistics show that 25% of a garment's carbon footprint comes from the way it is cared for, highlighting the importance of mindful washing practices.

-

Drying Techniques: Air drying is preferable to machine drying, as it minimises the risk of shrinkage and fabric damage. If using a dryer, opt for a low heat setting to further protect the garment.

-

Storage: Keep hoodies in a cool, dry location to avoid mildew and preserve their shape. Using padded hangers and garment bags can provide extra protection and help avoid stretching, ensuring the garment retains its intended fit.

-

Regular Inspections: Periodically check for signs of wear and tear, addressing issues such as loose threads or small holes promptly to prevent further damage. This proactive approach can significantly prolong the lifespan of the garment. Implementing a rotation system for mechanic sweatshirts can also help evenly distribute wear and prevent overuse of a single item.

Applying these practices not only maintains mechanic apparel from Jon Monsir Uniforms in excellent condition but also enhances a polished and professional look, emphasising the significance of attire care in different sectors.

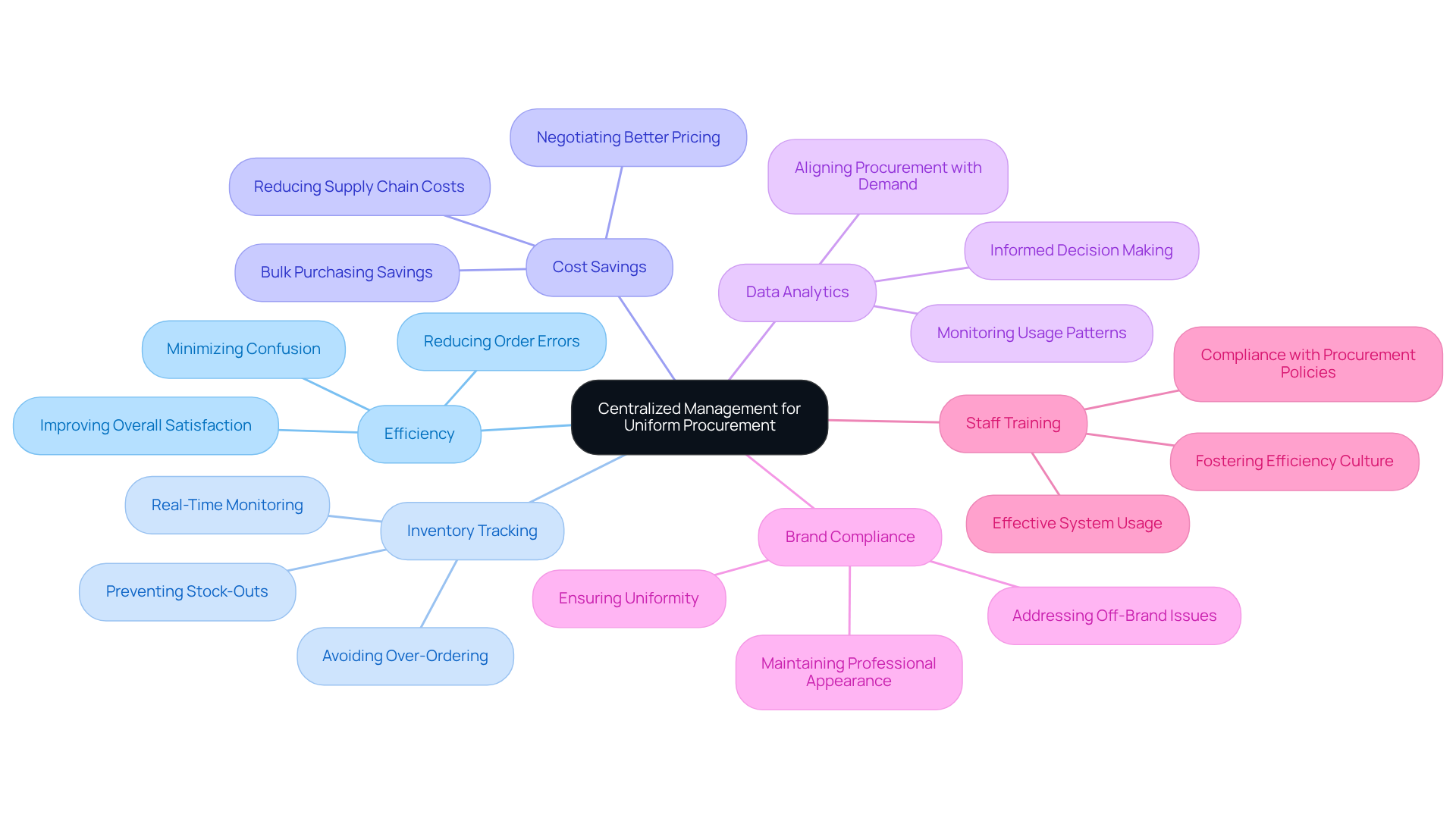

Utilize Centralized Management for Uniform Procurement

Implementing a centralised management system for uniform procurement can significantly enhance efficiency and consistency across an organisation.

A centralised system provides a single point of ordering for mechanic sweatshirts, minimising confusion and ensuring that all team members receive the same quality and style. This approach can reduce order errors and improve overall satisfaction. Jon's Custom Attire offers quick local supply and embroidery with national shipping, guaranteeing that outfits are easily accessible when needed.

Centralised management facilitates better tracking of inventory levels, helping to prevent stock-outs and over-ordering. With Jon Uniforms' inclusive sizing options ranging from 6 to 30, organisations can ensure that all employees are adequately outfitted. According to Harvard Business Review (2023), data-driven forecasting can decrease stockouts by as much as 30%, ensuring that apparel is accessible when needed without surplus inventory.

By consolidating purchases, organisations can negotiate better pricing with suppliers, leading to significant cost savings. Research from McKinsey & Company (2023) indicates that businesses that centralise procurement operations can reduce supply chain costs by up to 20%, enhancing budget management. Jon Attire's centralised ordering and management system supports this by providing visibility and control over clothing expenditures.

Utilising data analytics allows organisations to monitor usage patterns and make informed decisions about future orders and inventory needs. This proactive approach ensures that procurement aligns with actual demand, reducing waste and improving efficiency. The Jon Attire system enables organisations to maintain appearance and comfort through frequent wear and laundering cycles, ensuring that garments remain in good condition.

A centralised strategy ensures that all attire, including the mechanic sweatshirt, complies with brand guidelines, preserving a professional look throughout the organisation. This consistency reinforces brand identity and enhances team cohesion. Jon's attire solutions address issues such as off-brand logos and colour shifts, ensuring that all outfits accurately represent the company's branding.

Providing training for staff on how to effectively use the centralised system ensures smooth operations and compliance with procurement policies. Empowering employees with the right tools and knowledge fosters a culture of efficiency and accountability. Jon Monsir Uniforms is dedicated to assisting organisations in overcoming challenges associated with attire management.

By adopting a centralised management approach, organisations can enhance their uniform procurement processes, leading to improved efficiency and a more cohesive team appearance.

Conclusion

Choosing the right mechanic sweatshirt is crucial for ensuring comfort, durability, and professionalism in the demanding environment of mechanical work. By concentrating on essential features such as fabric quality, fit, moisture-wicking properties, and safety features, mechanics can make informed decisions that enhance their performance and safety on the job.

The importance of selecting sweatshirts made from sustainable materials and produced through ethical practises cannot be overstated. The environmental benefits of organic and recycled fabrics are significant, as are the implications of fair labour conditions. Investing in durable workwear not only supports these ethical practises but also offers long-term advantages. Furthermore, effective care and maintenance practises are vital for prolonging the lifespan of these garments, ensuring they remain functional and presentable.

Adopting a centralised management approach for uniform procurement can streamline the process, improve efficiency, and maintain consistency across teams. By prioritising quality, sustainability, and effective management strategies, organisations can enhance their operational effectiveness while contributing to a more responsible and professional image within the industry. Embracing these best practises is essential for anyone looking to optimise their workwear choices and foster a culture of excellence in the mechanical field.

Frequently Asked Questions

What are the essential features to look for in a mechanic sweatshirt?

Key features include durability, comfort and fit, moisture-wicking properties, functional pockets and tool loops, reinforced seams, safety features, and sustainability.

Why is durability important in mechanic sweatshirts?

Durability is crucial because it ensures the garment can withstand the rigours of mechanical work, reducing the need for frequent replacements.

What materials are recommended for mechanic sweatshirts?

High-quality materials such as cotton-polyester blends or ripstop fabrics are recommended for their durability.

How does comfort and fit affect the choice of mechanic sweatshirts?

A well-fitted sweatshirt allows for ease of movement, which is vital for comfort during long work hours, enabling mechanics to perform tasks efficiently.

What are moisture-wicking properties and why are they beneficial?

Moisture-wicking properties help keep mechanics dry and comfortable in hot working conditions, enhancing overall productivity.

How do pockets and tool loops improve productivity for mechanics?

Functional designs with pockets and tool loops allow essential items to be easily accessible, minimising disruptions during work.

What role do reinforced seams play in mechanic sweatshirts?

Reinforced seams enhance durability, making the sweatshirt less likely to tear and ensuring reliability in demanding environments.

Why are safety features important in mechanic sweatshirts?

Safety features, such as reflective strips or high-visibility colours, improve visibility in low-light conditions, reducing the risk of accidents in busy workshops.

How does sustainability factor into the selection of mechanic sweatshirts?

Choosing garments made from sustainable materials contributes to environmentally conscious practises and supports a greener future.

What should mechanics prioritise when selecting sweatshirts?

Mechanics should prioritise durability, comfort, moisture-wicking properties, functional designs, reinforced seams, safety features, and sustainability to ensure exceptional performance and a professional image.