Introduction

Ordering custom mechanic shirts is crucial for establishing a professional and cohesive team image. However, many organisations often overlook the details that can significantly impact this process. By prioritising:

- High-quality materials

- Accurate sizing

- Effective customisation

- Efficient ordering practices

businesses can enhance their brand identity while also boosting employee satisfaction and performance. Yet, with numerous options and potential challenges, how can companies ensure they make the best choices tailored to their specific needs? This article explores four essential best practises that will enable organisations to navigate the complexities of ordering custom mechanic shirts with confidence.

Select High-Quality Materials for Durability and Comfort

When ordering custom mechanic shirts, it is crucial to prioritise materials that ensure both durability and comfort. Here are some options to consider:

-

Cotton-Polyester Blends: These blends provide breathability and moisture-wicking properties, which are essential for mechanics working in hot and humid environments. They enhance comfort while offering stain resistance and ease of cleaning, vital for frequent exposure to grease and oil in the workshop.

-

High-Quality Cotton Drill Fabric: Renowned for its robustness and comfort, this fabric remains a popular choice in the industry.

-

Fabric Specifications: For optimal performance, seek fabrics with a GSM of 190-270, as these are well-suited for transitional seasons or indoor trades.

To ensure satisfaction with your order, always request fabric samples from suppliers to assess quality before committing to bulk purchases. This practise helps guarantee that the selected materials meet the rigorous demands of the engineering profession.

At Jon Monsir Uniforms, we take fabric performance seriously. Our materials undergo independent testing with Intertek Testing Services and Qualspec Testing Centre to verify durability, including assessments for colour fastness, water resistance, and more. This thorough testing ensures that our products not only meet but exceed industry standards, providing you with the assurance that your custom mechanic shirts will perform reliably in challenging settings.

Ensure Accurate Sizing and Fit for Optimal Performance

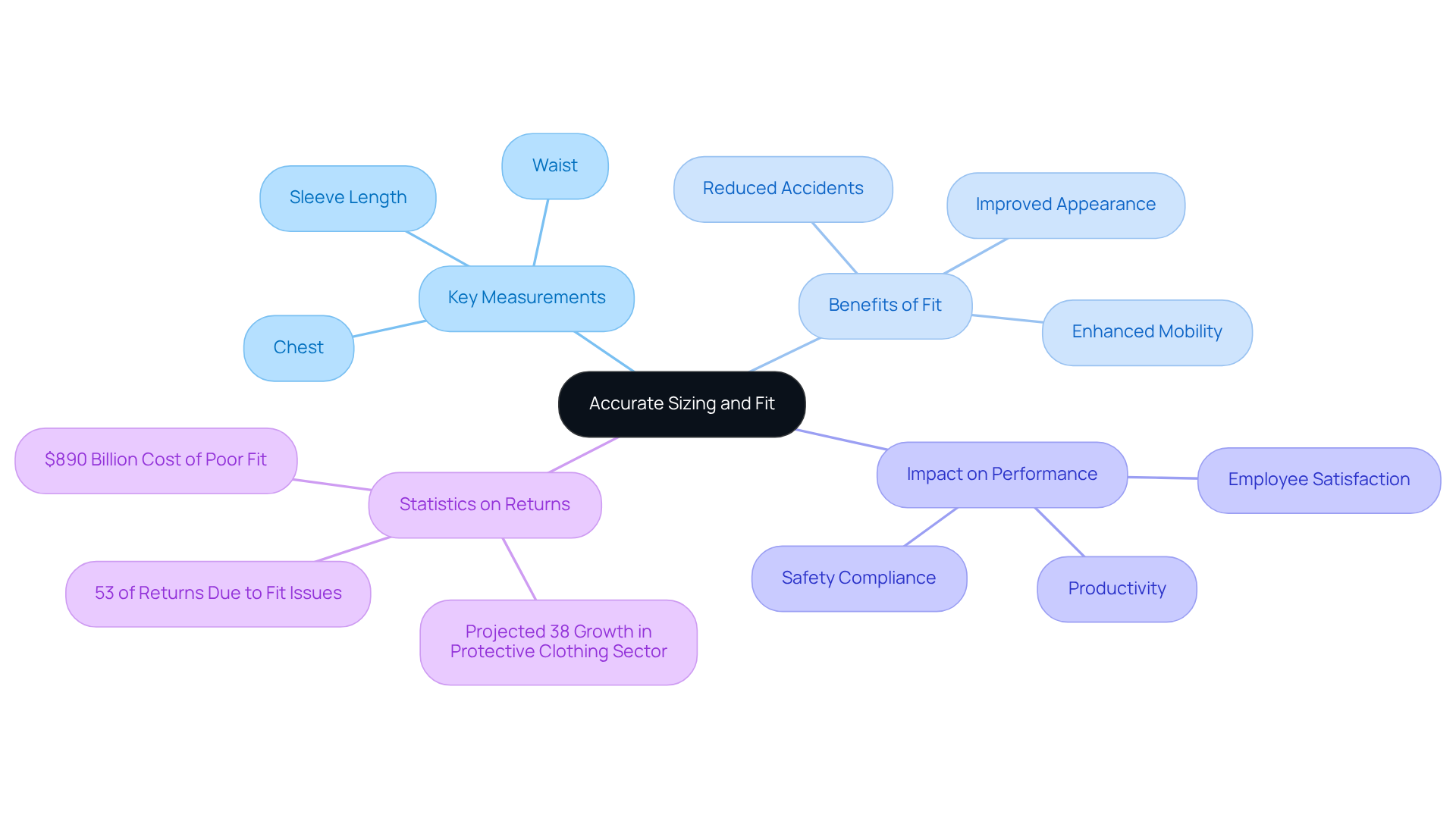

To achieve the best fit for custom mechanic shirts, utilising detailed sizing charts from suppliers and taking precise measurements of your team is essential. Key areas to measure include the chest, waist, and sleeve length, ensuring the garment lies flat during measurement. Encouraging team members to try on samples can significantly enhance comfort and mobility. A well-fitted garment not only improves the professional appearance of your team but also facilitates ease of movement, thereby reducing the likelihood of accidents in the workshop.

Research shows that improperly fitting personal protective equipment (PPE) can hinder movement and dexterity, negatively impacting task execution. Implementing a fitting session before placing a large order can lead to improved satisfaction and performance, as accurate sizing directly influences safety and productivity in the automotive industry. Organisations that prioritise fit have reported enhanced employee performance and decreased return rates, underscoring the importance of investing in well-fitted uniforms.

Notably, 53% of all clothing returns are due to size and fit issues, costing companies and retailers approximately $890 billion. With the protective clothing sector projected to grow by 38% in the next seven years, ensuring proper fit becomes increasingly vital.

Utilize Customization Options to Enhance Brand Identity

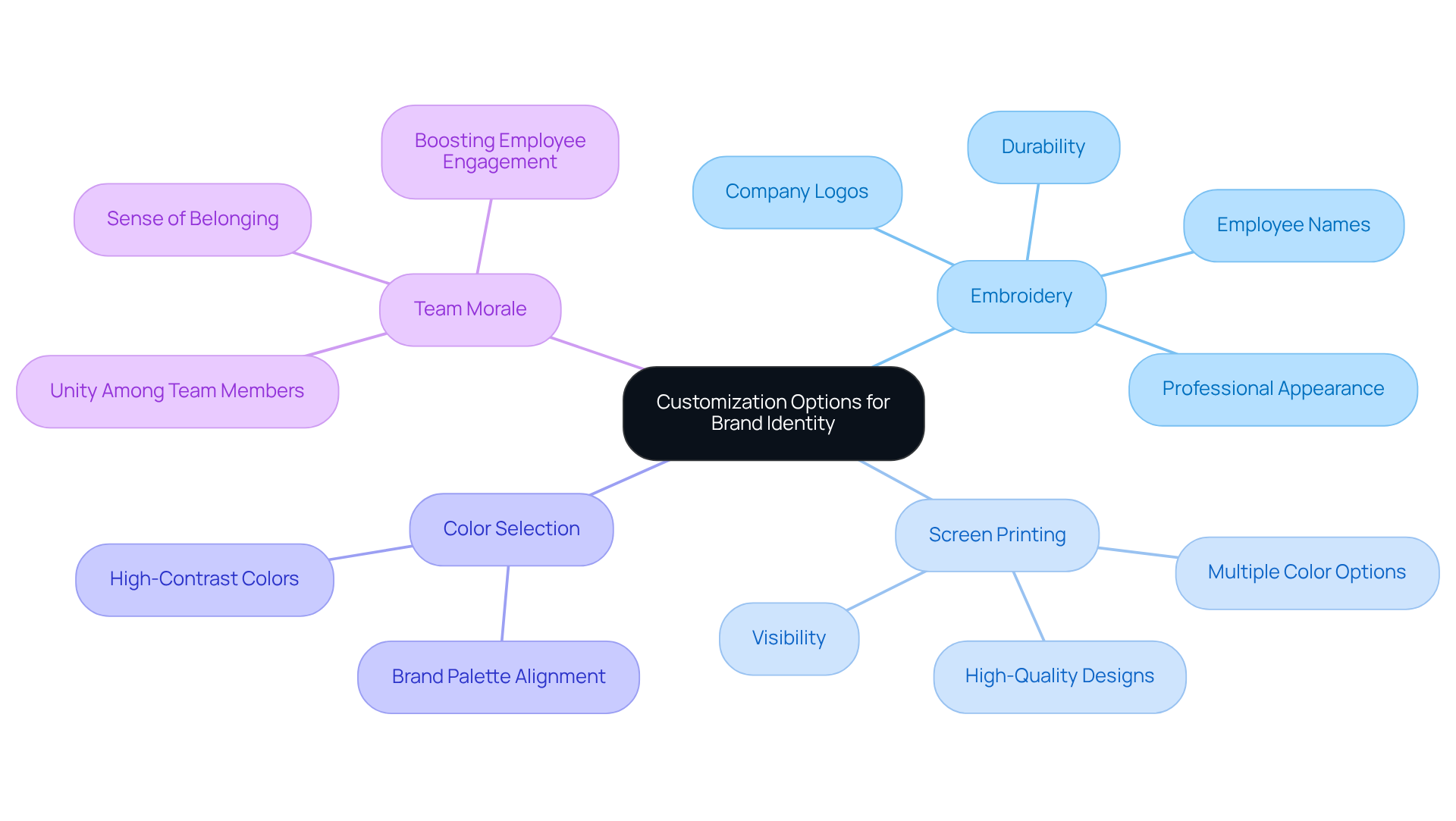

The customization of custom mechanic shirts is crucial for enhancing company identity. Options like embroidery and screen printing allow for the inclusion of company logos, employee names, and distinctive designs that reflect your brand's essence. Selecting colours that align with your palette is vital; high-contrast colours for logos significantly improve visibility and recognition, making your brand more memorable. Custom mechanic shirts not only promote a professional appearance but also foster a sense of belonging among team members, thereby boosting unity and morale. Working closely with your supplier to explore various customization techniques ensures that your design requirements are effectively met. Companies such as Coca-Cola illustrate the successful application of embroidered promotional clothing to sustain brand visibility and engage consumers, highlighting the effectiveness of well-executed branding strategies.

Streamline the Ordering Process for Efficiency and Timeliness

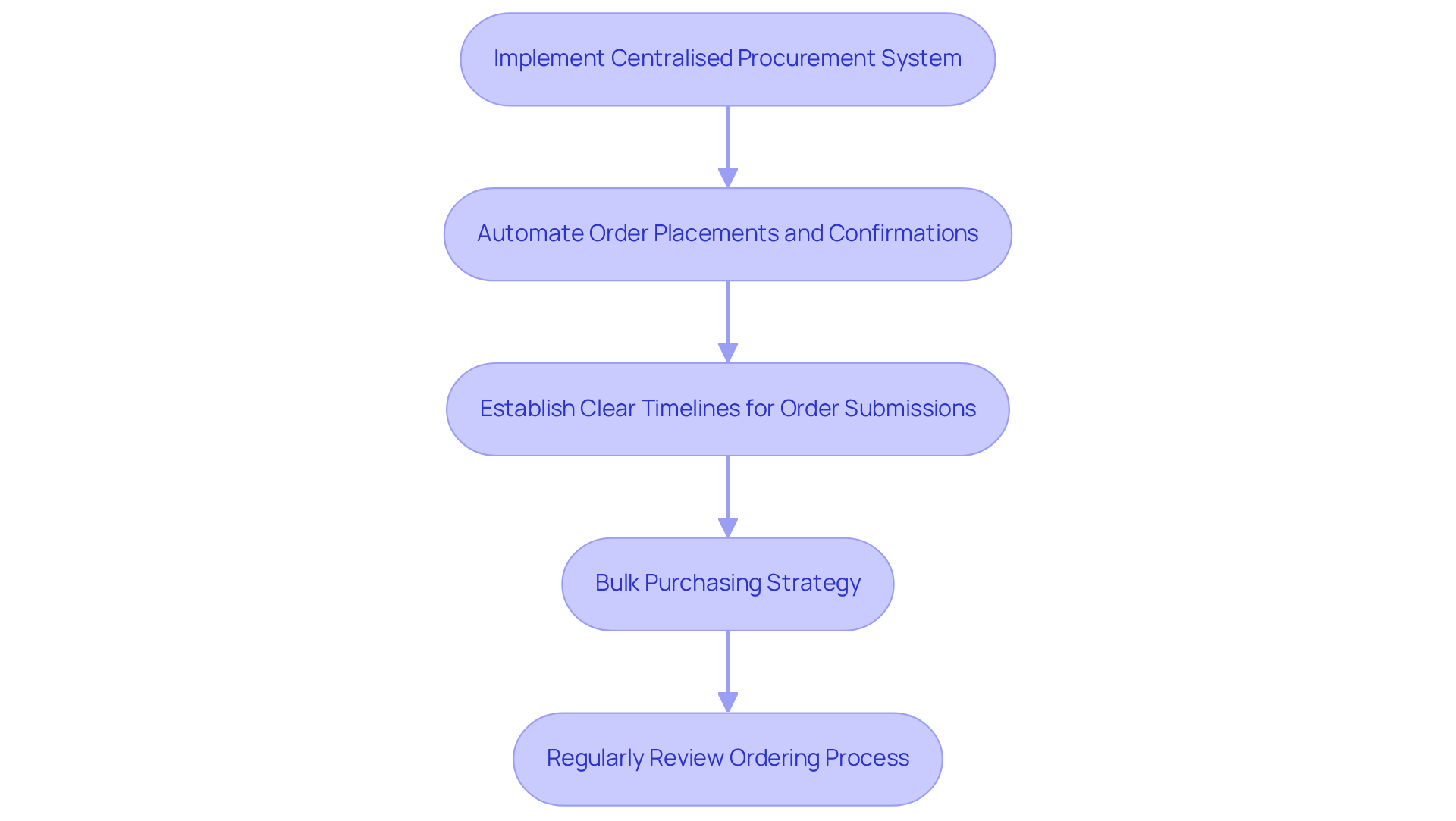

Implementing a centralised procurement system is essential to enhance the efficiency of acquiring custom mechanic shirts. This system allows for easy tracking and management of inventory, providing real-time visibility across multiple locations. By automating order placements and confirmations, organisations can significantly reduce administrative time; studies indicate that automation can lead to a 30% decrease in order processing times. Establishing clear timelines for order submissions and effectively communicating these with your team ensures alignment and accountability.

Bulk purchasing is another strategy that can yield substantial cost savings and expedite turnaround times. Organisations that have adopted centralised systems report improved adherence to safety regulations and brand standards, as these systems enforce uniform procurement procedures while allowing for local flexibility. Regularly reviewing the ordering process helps identify areas for improvement, ensuring that your uniform supply chain remains agile and responsive to evolving needs. For instance, organisations utilising automated inventory management have seen holding costs decrease by up to 25%, demonstrating the financial benefits of streamlined operations. By embracing these best practises, businesses can optimise their uniform management processes, particularly for custom mechanic shirts, and enhance overall operational efficiency.

Conclusion

Ordering custom mechanic shirts effectively requires a comprehensive approach that emphasises quality, fit, branding, and efficiency. By prioritising high-quality materials, ensuring accurate sizing, utilising customization options, and streamlining the ordering process, organisations can create uniforms that not only present a professional image but also enhance team performance and safety.

Key insights from this discussion underscore the significance of selecting durable fabrics, such as cotton-polyester blends and high-quality cotton drill, which offer both comfort and longevity. Accurate sizing is essential to avoid fit-related issues that could compromise safety and productivity. Moreover, thoughtful customization options enable businesses to reinforce their brand identity and cultivate team spirit. Implementing a centralised procurement system can greatly improve the efficiency of the ordering process, leading to cost savings and enhanced operational agility.

In summary, embracing these best practises for ordering custom mechanic shirts transcends mere aesthetics; it represents a strategic choice that can positively impact employee morale, brand visibility, and overall workplace safety. By dedicating time and resources to these considerations, companies can ensure their uniforms not only fulfil job requirements but also effectively represent their brand in a competitive market.

Frequently Asked Questions

Why is it important to select high-quality materials for custom mechanic shirts?

Selecting high-quality materials is crucial for ensuring both durability and comfort, which are essential for mechanics who work in demanding environments.

What are some recommended materials for custom mechanic shirts?

Recommended materials include cotton-polyester blends for breathability and moisture-wicking properties, and high-quality cotton drill fabric known for its robustness and comfort.

What fabric specifications should I look for when ordering mechanic shirts?

For optimal performance, look for fabrics with a GSM (grams per square meter) of 190-270, as these are suitable for transitional seasons or indoor trades.

How can I ensure the quality of the fabric before making a bulk purchase?

It is advisable to request fabric samples from suppliers to assess the quality before committing to bulk purchases.

How does Jon Monsir Uniforms ensure the quality of their materials?

Jon Monsir Uniforms ensures quality by having their materials undergo independent testing with Intertek Testing Services and Qualspec Testing Centre to verify durability, including assessments for colour fastness and water resistance.

What is the benefit of the thorough testing conducted on the fabrics?

The thorough testing ensures that the products not only meet but exceed industry standards, providing assurance that the custom mechanic shirts will perform reliably in challenging settings.