Introduction

Mechanic name patches are essential for establishing brand identity and professionalism in the automotive industry. These patches not only serve as a means of identification but also contribute to a cohesive brand image. By examining different types of patches, customization options, and effective management strategies, organisations can improve operational efficiency and boost employee morale.

As the demand for sustainability increases, businesses face the challenge of balancing durability with eco-friendly practises. It is crucial for companies to consider how their mechanic name patch management can align with both their brand values and environmental responsibility. This alignment not only enhances brand reputation but also meets the growing expectations of consumers and stakeholders.

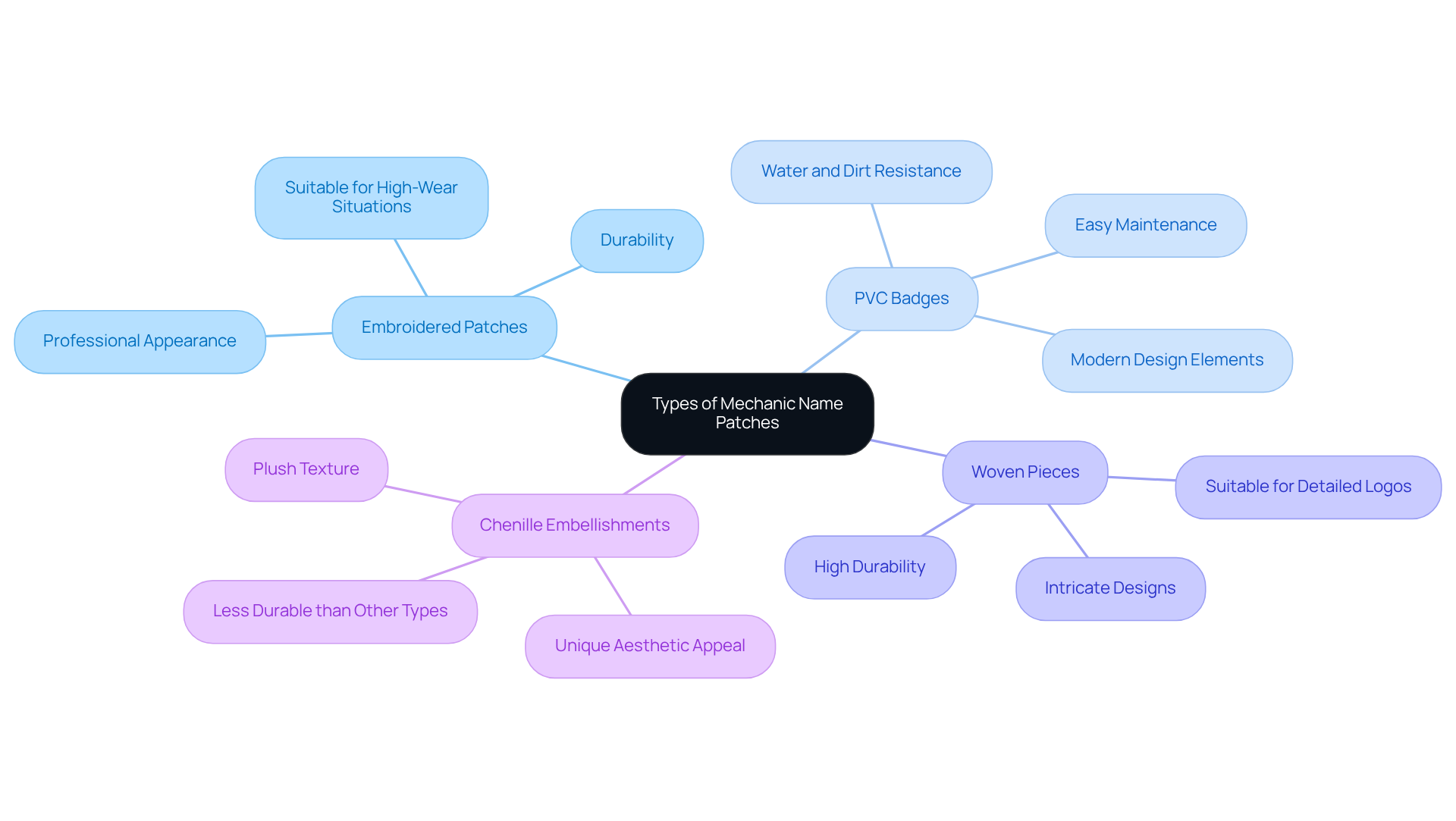

Understand Types and Materials of Mechanic Name Patches

Mechanic name labels come in various materials, each offering distinct advantages tailored to the automotive sector's needs. The primary types include:

-

Embroidered Patches: These patches are made from threads stitched onto a robust fabric backing, known for their durability. They withstand frequent washing and harsh working conditions, making them an ideal choice for mechanics who need reliable identification in demanding environments.

-

PVC Badges: Constructed from soft plastic, PVC badges are highly resistant to water and dirt, simplifying cleaning and maintenance. Their durability makes them suitable for outdoor use, where exposure to the elements is a significant concern.

-

Woven Pieces: Created by intertwining threads, these pieces allow for intricate designs and subtle details. They are exceptionally durable and well-suited for high-wear situations, ensuring that the repair maintains its appearance over time.

-

Chenille Embellishments: Recognised for their plush, fuzzy texture, chenille embellishments provide a unique aesthetic appeal. However, they may not match the durability of embroidered or woven options, making them less suitable for environments prone to wear and tear.

When selecting materials, it's crucial to consider the working environment, washing frequency, and desired aesthetic. For instance, embroidered insignias are often favoured in automotive settings due to their durable quality and professional look. Furthermore, emerging trends in 2026 indicate a growing preference for PVC and woven emblems, which combine durability with modern design elements, addressing the evolving needs of the industry. Understanding these materials and their applications can significantly enhance the effectiveness of mechanic name management.

Leverage Customization for Enhanced Brand Identity

Customization of mechanic name patches is essential for enhancing the company's identity. Here are effective strategies to consider:

- Incorporate Company Colours: Using colours that align with your brand’s palette creates a cohesive look across uniforms. This consistency strengthens recognition and fosters a unified team appearance, which is crucial in sectors where professionalism is key. At Jon Monsir Uniforms, we ensure that our embroidery service accurately reflects your company colours, enhancing your visibility.

- Add Logos: Including the company logo on patches boosts identity and promotes recognition among customers. A well-placed logo serves as a visual cornerstone, making the brand memorable and easily identifiable. Our embroidery service at Jon Monsir Uniforms guarantees precise logo placement for maximum impact.

- Personalization: Allowing staff to add their names or titles fosters a sense of ownership and pride in their work attire. Research shows that personalised uniforms can increase employee satisfaction by up to 20%, which in turn enhances service quality and performance. At Jon Monsir Uniforms, our expert team ensures that each name label is crafted with precision, reflecting the quality and durability our brand represents.

- Unique Designs: Consider creating distinctive shapes or styles that embody the company’s values or mission. For instance, a mechanic shop committed to sustainability might select a mechanic name patch made from eco-friendly materials, aligning their branding with their operational ethos. Jon Monsir Uniforms offers tailored uniform solutions that meet aesthetic needs while adhering to sustainable practises, ensuring a comprehensive approach to branding.

By utilising these customization options, businesses can achieve a professional appearance that resonates with customers while significantly enhancing staff satisfaction and team spirit. However, it is vital to avoid common pitfalls such as overcomplicating designs or neglecting the importance of uniformity in branding. Ultimately, effective customization can lead to a stronger brand identity and improved employee morale.

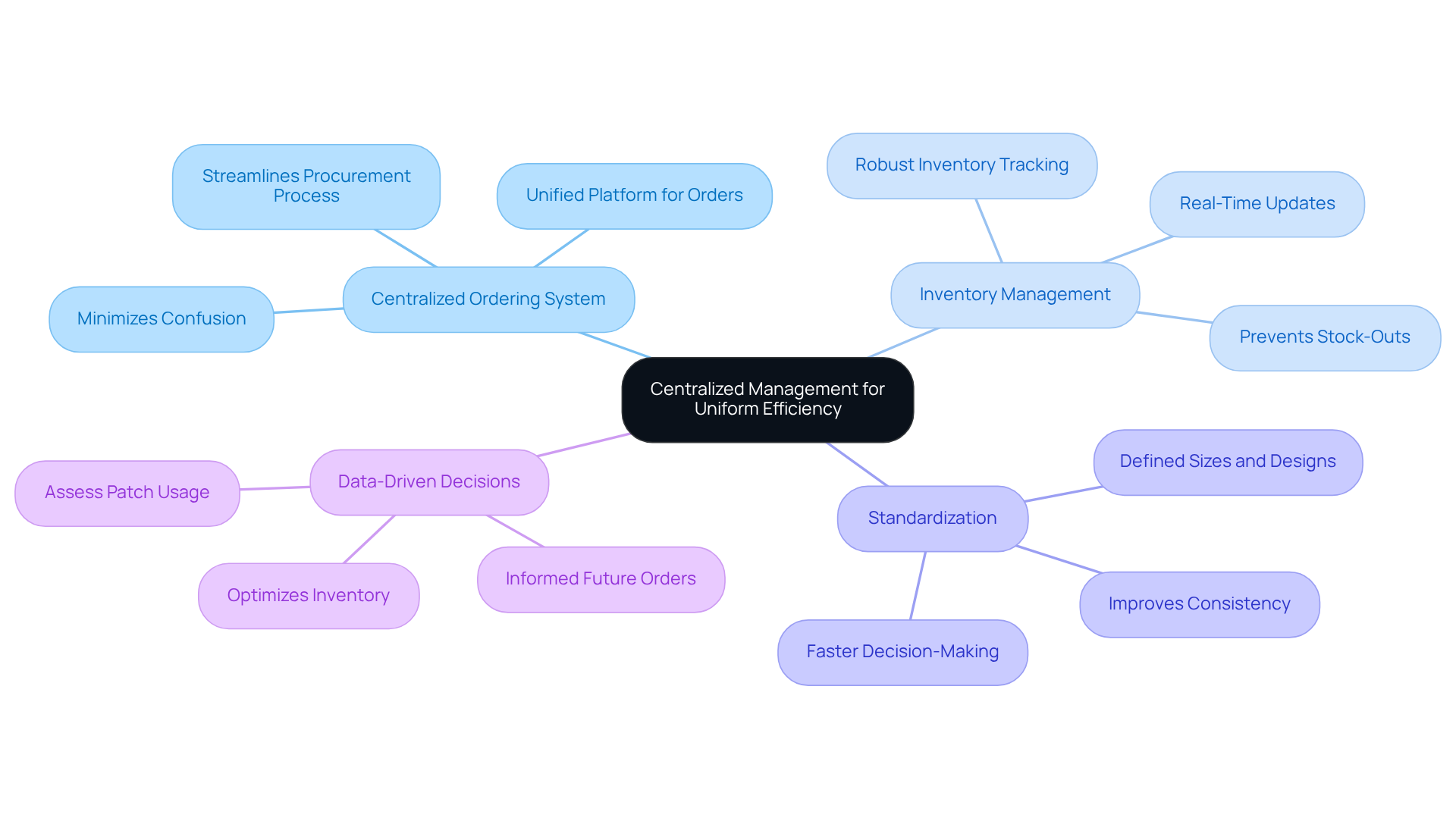

Implement Centralized Management for Uniform Efficiency

Centralised management of mechanic name patches significantly enhances operational efficiency. To achieve this, consider the following essential practises:

-

Centralised Ordering System: Establish a unified platform for all patch orders. This approach minimises confusion and ensures consistency across orders by utilising the mechanic name patch, streamlining the procurement process.

-

Inventory Management: Implement robust inventory tracking to prevent stock-outs and guarantee timely replenishment. Utilising software that provides real-time inventory updates enhances responsiveness and reduces delays in clothing provisioning.

-

Standardisation: Define standard sizes and designs for emblems to simplify the ordering process and ensure uniformity across all uniforms. This not only improves the consistency of the identity but also enables faster decision-making.

-

Data-Driven Decisions: Utilise data analytics to assess patch usage and staff preferences. This insight allows organisations to make informed decisions regarding future orders and designs, optimising inventory and reducing waste.

By centralising management, organisations can alleviate administrative burdens, enhance efficiency, and ensure that all employees present a cohesive brand image with the mechanic name patch. Statistics indicate that effective inventory management can improve operational efficiency by up to 30%, making centralised systems a vital component of successful uniform programmes.

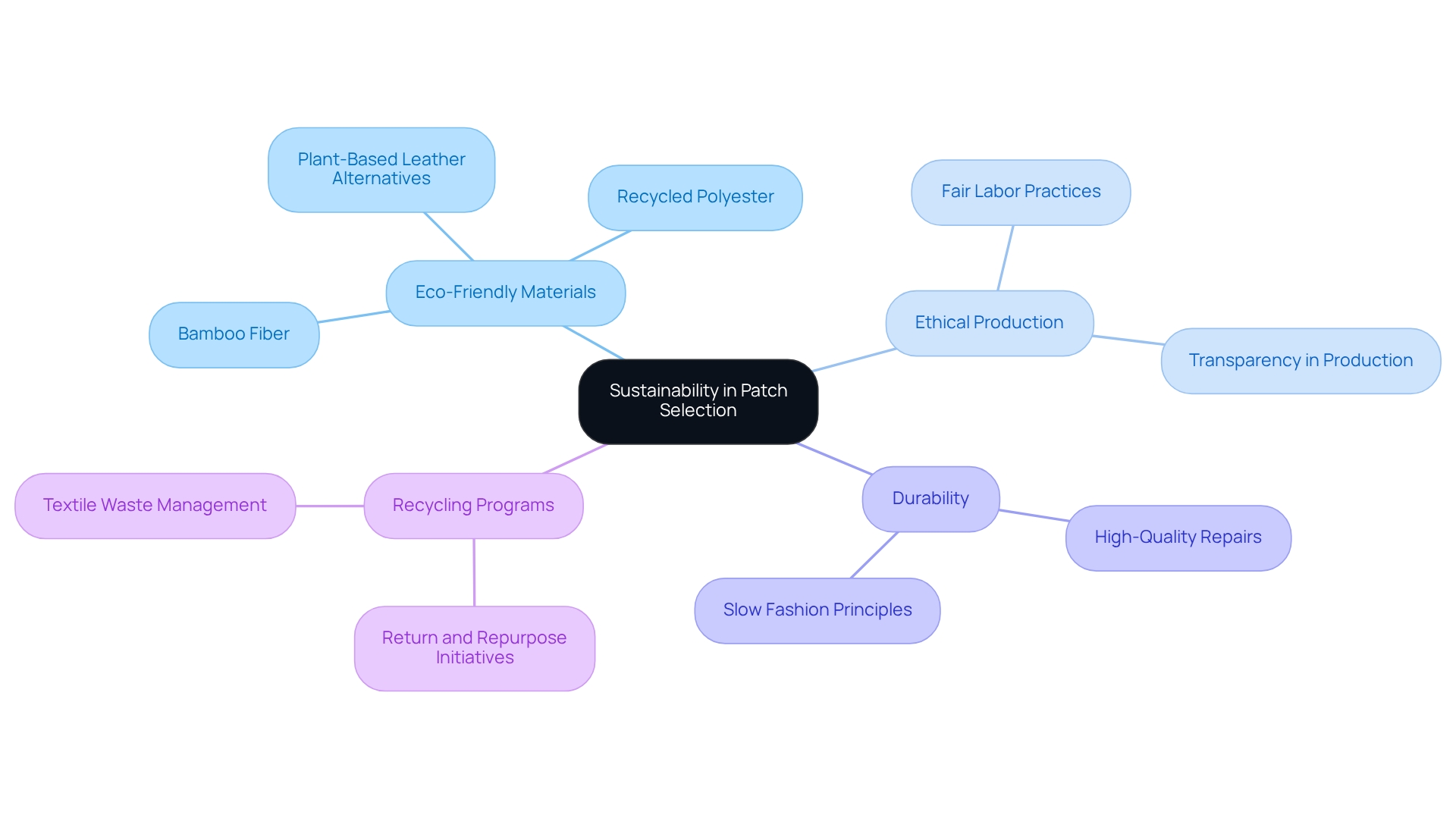

Prioritize Sustainability in Patch Selection

Sustainability is a crucial factor when selecting mechanic name patch labels. Here are some best practices to consider:

- Choose Eco-Friendly Materials: Select patches made from sustainable materials like recycled polyester or bamboo fibre. These options minimise environmental impact while providing durability and comfort. However, it’s essential to manage bamboo cultivation carefully to prevent adverse environmental effects.

- Ethical Production: Ensure that products are manufactured in facilities that comply with fair labour practices and environmental standards. Transparency in production is vital, as it fosters trust and accountability within the supply chain, reflecting Jon Monsir Uniforms' commitment to ethical sourcing.

- Durability: Opt for high-quality repairs that withstand wear and tear, reducing the need for frequent replacements and minimising waste. This approach aligns with the principles of slow fashion and supports Jon Monsir Uniforms' sustainability goals.

- Recycling Programs: Establish a recycling program for old patches or uniforms, encouraging employees to return worn items for proper disposal or repurposing. This initiative is increasingly important given the significant rise in textile waste since 2017.

By prioritising sustainability, organisations can enhance their brand reputation and make a positive contribution to the environment while effectively meeting their operational needs.

Conclusion

Effective mechanic name patch management is crucial for enhancing brand identity, improving operational efficiency, and promoting sustainability within the automotive sector. By understanding the various types and materials of patches, businesses can make informed decisions that align with their specific needs and working environments. This strategic selection not only ensures durability but also fosters a professional appearance that resonates with both customers and employees.

The article outlines four best practises for successful mechanic name patch management:

- Selecting the right materials

- Leveraging customization for brand identity

- Implementing centralised management for uniform efficiency

- Prioritising sustainability

Each of these practises is essential in creating a cohesive and recognisable brand image, streamlining operations, and minimising environmental impact. From incorporating company colours and logos to establishing a centralised ordering system, these insights empower organisations to optimise their patch management strategies.

In a rapidly evolving industry, adopting these best practises can lead to significant enhancements in employee morale, customer recognition, and operational effectiveness. By prioritising quality, customization, and sustainability, businesses not only strengthen their brand identity but also contribute positively to the environment. Implementing these strategies will ensure that mechanic name patches serve as a powerful tool in fostering a professional image and a unified team spirit, ultimately driving success in the competitive automotive landscape.

Frequently Asked Questions

What are the main types of mechanic name patches?

The main types of mechanic name patches include embroidered patches, PVC badges, woven pieces, and chenille embellishments.

What are embroidered patches made of and what are their advantages?

Embroidered patches are made from threads stitched onto a robust fabric backing. They are durable, withstand frequent washing and harsh working conditions, making them ideal for mechanics in demanding environments.

What are the characteristics of PVC badges?

PVC badges are constructed from soft plastic and are highly resistant to water and dirt, making them easy to clean and maintain. Their durability makes them suitable for outdoor use where exposure to the elements is a concern.

How are woven pieces created and what are their benefits?

Woven pieces are created by intertwining threads, allowing for intricate designs and subtle details. They are exceptionally durable and well-suited for high-wear situations, ensuring they maintain their appearance over time.

What are chenille embellishments known for?

Chenille embellishments are recognised for their plush, fuzzy texture, providing a unique aesthetic appeal. However, they may not be as durable as embroidered or woven options, making them less suitable for wear-prone environments.

What factors should be considered when selecting materials for mechanic name patches?

When selecting materials, it's important to consider the working environment, washing frequency, and desired aesthetic. For example, embroidered insignias are often preferred in automotive settings for their durability and professional look.

What trends are emerging in mechanic name patches for 2026?

Emerging trends indicate a growing preference for PVC and woven emblems, which combine durability with modern design elements, addressing the evolving needs of the automotive industry.