Introduction

Creating an embroidered logo is an art that merges creativity with technical precision. However, many brands find it challenging to strike the right balance. This article explores essential practises for crafting an effective embroidered logo, ensuring it captures attention and endures over time.

What challenges may arise during the design process?

How can brands effectively navigate the complexities of embroidery specifications, colour choices, and uniform integration to leave a lasting impression?

Define Logo Specifications for Embroidery

To create an effective embroidered design, start by defining its specifications. This involves determining the size, shape, and complexity of the design. For stitching, designs should be straightforward and striking, avoiding complex details that may not translate well onto fabric. A good rule of thumb is to keep the emblem within a width of 3 to 4 inches for chest placements, ensuring legibility and visual appeal. The maximum embroidery area for chest placements is 4 × 4 inches, which is crucial when creating your design.

Additionally, the minimum text height should be at least 0.25 inches to maintain clarity when stitched, while the minimum recommended thickness for text and lines is 0.05 inches. Providing a vector file format, such as .AI or .EPS, is essential for accurate digitization, as these formats allow for scaling without loss of quality. It's important to note that digitization fees start at around $6.50 for basic designs, which should be factored into budget planning.

Adhering to these guidelines will help ensure that your embroidered logo effectively reflects your brand while avoiding common issues like excessive detail and poor readability.

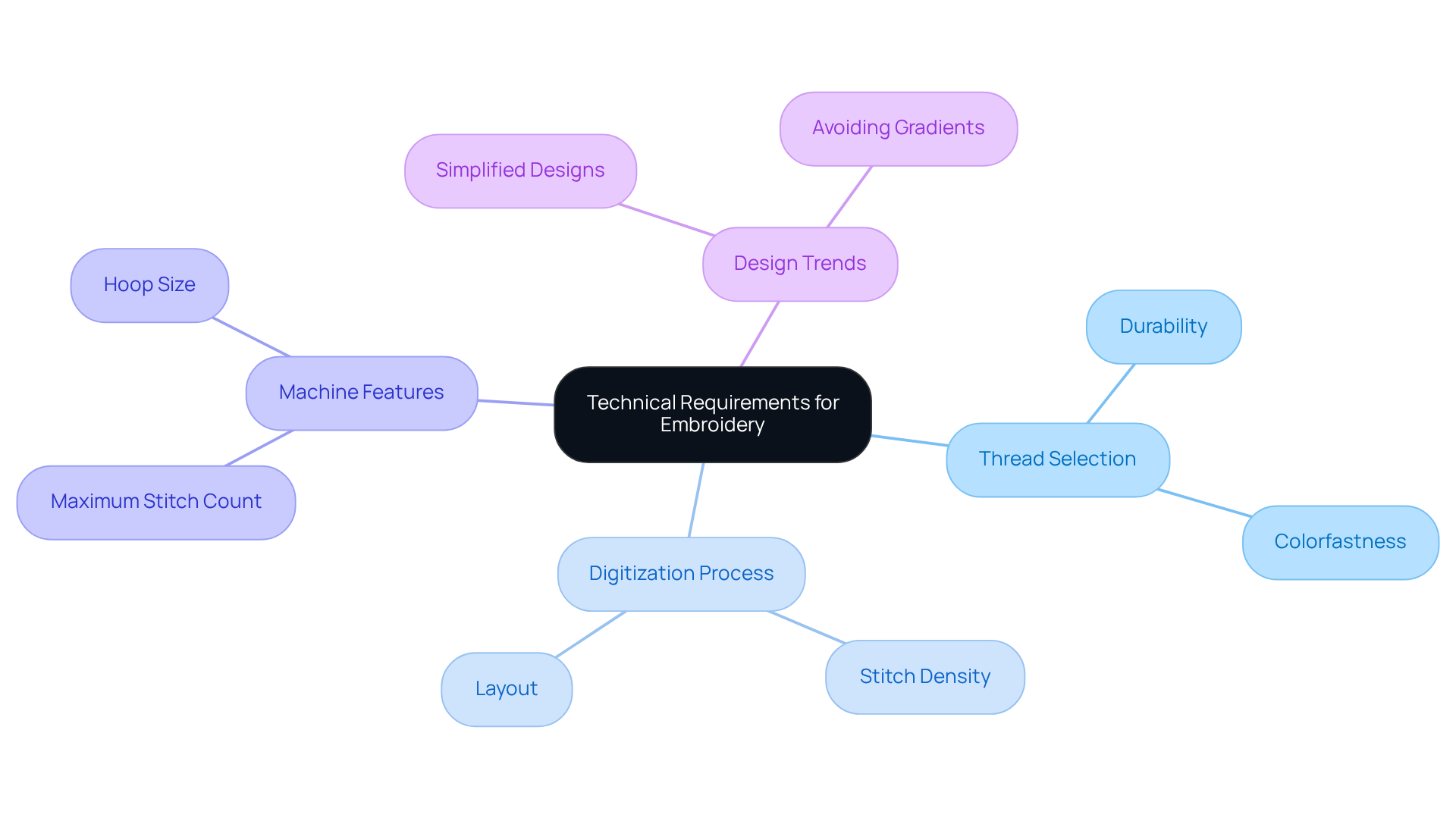

Understand Technical Requirements for Embroidery

Creating a design for stitching requires a solid understanding of the technical requirements involved. Selecting the right thread type is essential; choose durable and colorfast threads that can endure frequent washing and wear. Polyester threads, particularly 40-weight, are widely used for their vibrancy and resilience.

Equally important is the digitization process, which transforms your emblem into a stitch file compatible with sewing machines. This process involves ensuring the layout is digitised with the appropriate stitch density - typically between 4,000 to 7,000 stitches per square inch - to avoid issues such as thread breaks or misalignment.

Familiarise yourself with your sewing machine's features, including its maximum stitch count and hoop size, to ensure your design fits within these parameters. Current trends highlight the use of simplified designs, steering clear of gradients and ultra-fine details that can complicate the embroidery process.

By adhering to these best practises, you can create a professional and durable design with an embroidered logo that effectively represents your brand.

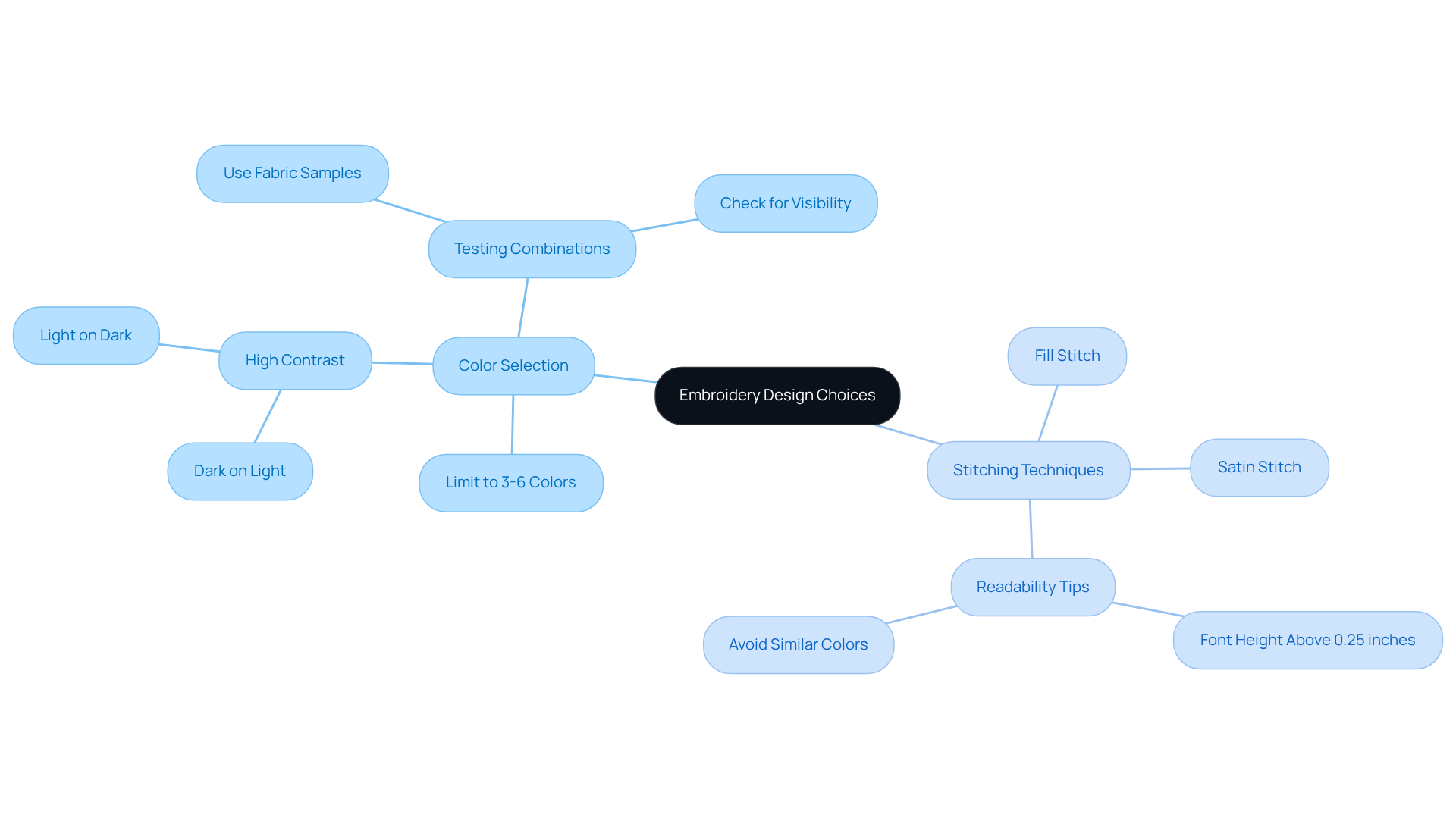

Choose Colors and Stitching Techniques Wisely

Selecting the right hues for your embroidered design is crucial for ensuring its impact and visibility. Aim to limit your selection to three to six colours; this simplicity enhances recognizability. High contrast between the emblem and the garment colour significantly boosts visibility. For example, a dark emblem on a light background or vice versa is particularly effective.

The choice of stitching technique also plays a vital role in the overall appearance of the emblem. Techniques like satin stitch or fill stitch can create different textures and visual effects, contributing to the design's impact. Testing hue combinations on fabric samples is essential, as shades may look different when stitched compared to their digital representation. This practise not only helps achieve the desired aesthetic but also ensures that the emblem remains clear and legible from a distance, reinforcing brand identity.

For crisp, readable small text, keep font heights above 0.25 inches and avoid using colours that are too similar in value to prevent blending. As Nancy Lin states, 'Embroidery is about bold, readable impact, not photographic realism.

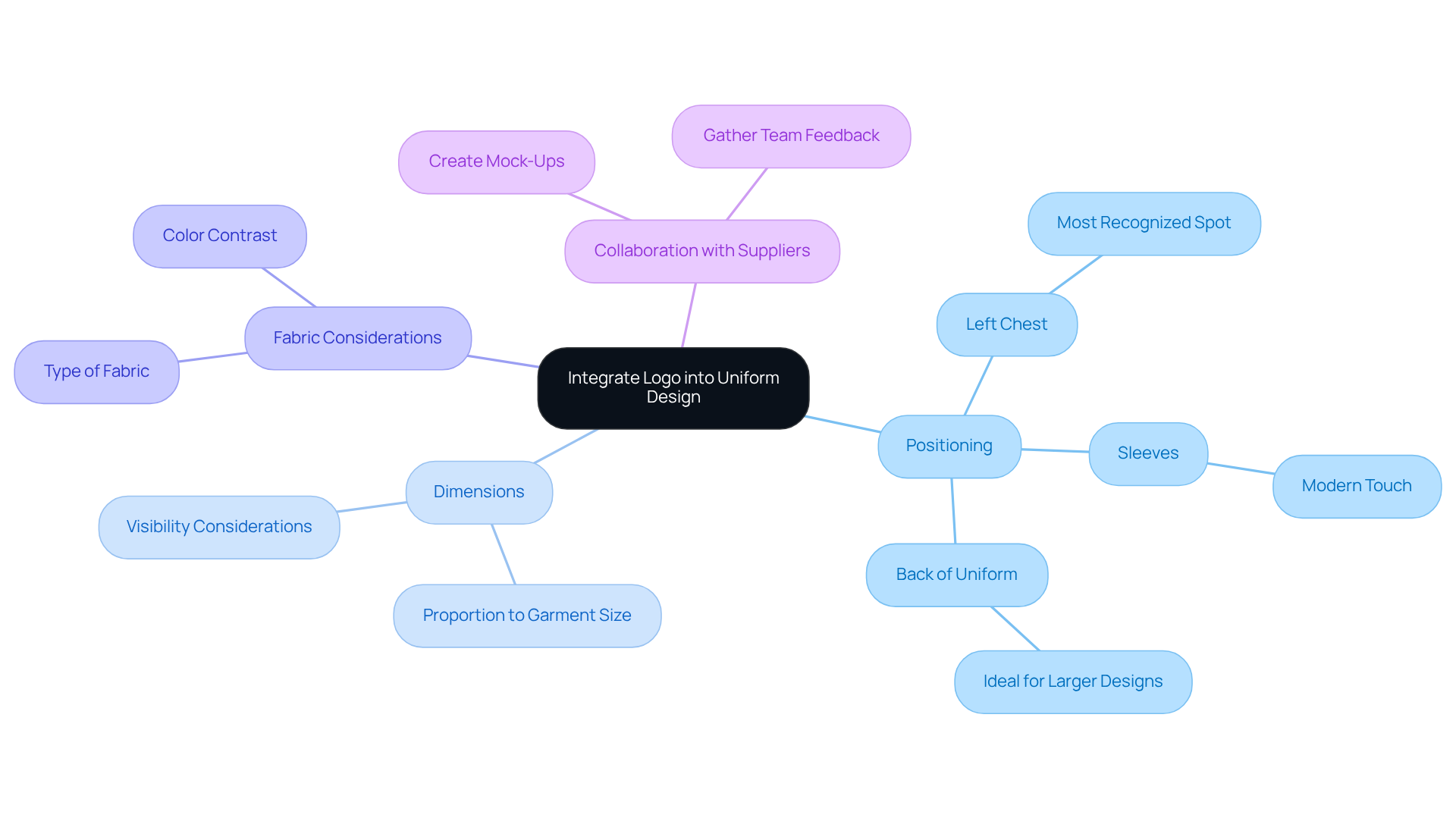

Integrate Logo into Uniform Design Effectively

To effectively incorporate your emblem into clothing creation, consider the positioning and dimensions of the emblem on the garment. Common placements include:

- The left chest area

- Sleeves

- Back of the uniform

The left chest is the most recognised spot for visibility at eye level. The back is ideal for larger layouts, particularly in situations where staff frequently turn away from clients. Ensure that the emblem is proportionate to the garment size; it should be noticeable without overshadowing the uniform's design. Additionally, consider the fabric type and colour of the uniform, as these factors can influence the emblem's appearance, with high-contrast colours enhancing visibility.

At Jon Monsir Uniforms, our expert team delivers custom embroidery that includes an embroidered logo, reflecting your brand’s identity with detail and durability. Collaborate with your uniform supplier to create mock-ups that display the design on the uniform, allowing for modifications before final production. This approach ensures that the emblem not only reinforces brand identity but also complements the uniform's aesthetic, creating a cohesive and professional appearance. Remember, intricate designs may not translate well to embroidery, so simplicity is key to maintaining logo integrity.

Conclusion

In conclusion, creating an effective embroidered logo requires a thoughtful approach that encompasses several essential practises. The key to success lies in:

- Defining logo specifications

- Understanding technical requirements

- Selecting appropriate colours and stitching techniques

- Integrating the logo seamlessly into uniform designs

By focusing on these aspects, brands can ensure their embroidered logos not only stand out but also accurately represent their identity.

Throughout this article, we have emphasised important guidelines. Defining logo specifications involves considering size, complexity, and clarity to ensure the design translates well onto fabric. Understanding technical requirements, such as thread selection and digitisation processes, is crucial for achieving both durability and visual appeal. Additionally, selecting the right colours and stitching techniques can significantly enhance the logo's impact, while effective integration into uniform designs ensures visibility and cohesion.

Ultimately, the creation of an embroidered logo is a blend of art and science. By adhering to these best practises, brands can develop logos that are not only visually striking but also practical and representative of their values. Embrace these insights to elevate your branding efforts, ensuring that your embroidered logo leaves a lasting impression on your audience.

Frequently Asked Questions

What are the key specifications to define for an embroidered logo?

Key specifications include determining the size, shape, and complexity of the design, ensuring it is straightforward and striking.

What is the recommended size for chest placements of embroidered logos?

The emblem should be within a width of 3 to 4 inches for chest placements, with a maximum embroidery area of 4 × 4 inches.

What is the minimum text height for embroidery to maintain clarity?

The minimum text height should be at least 0.25 inches.

What is the minimum recommended thickness for text and lines in embroidery?

The minimum recommended thickness for text and lines is 0.05 inches.

Why is it important to provide a vector file format for embroidery designs?

Providing a vector file format, such as .AI or .EPS, is essential for accurate digitization, as these formats allow for scaling without loss of quality.

What are the typical costs associated with digitization for embroidery?

Digitization fees start at around $6.50 for basic designs, which should be included in budget planning.

What common issues should be avoided when creating an embroidered logo?

Common issues to avoid include excessive detail and poor readability in the design.